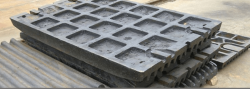

Direct-bonded Magnesia Chrome Bricks

Direct-bonded magnesia chrome bricks are made from high grade magnesite clinker and chrome oxide. By high pressure shaping and high temperature firing, its characteristic is the high direct-bonding rate, and big crystallite. It has a good thermal spalling resistance. The low–basic neutral nature gives itself a good slag resistance when servicing low–acid feed furnaces. The brick is a realistic lining material for refining furnace, electric furnace, glass melting furnace and cement rotary kiln etc.

Magnesia chrome bricks are refractory bricks made of a mixture of magnesia (MgO) and chromium oxide (Cr2O3). They are known for their high refractoriness (the ability to withstand high temperatures), excellent thermal shock resistance, and good chemical stability.

Features:

High refractoriness: can withstand temperatures up to 1750 °C

Excellent thermal shock resistance: can withstand rapid temperature changes without cracking or breaking

Good chemical stability: resistant to attack from most acids and alkalis

High strength: strong enough to withstand heavy loads and wear and tear

Good insulation properties: help to maintain consistent temperatures in high-temperature environments

Applications:

Used in the lining of furnaces and kilns in various industries such as steel, glass, cement, and petrochemical.

Also used in the manufacturing of ceramics, non-ferrous metals, and other refractory materials.

Can be used in the construction of high-temperature equipment such as heat exchangers, boilers, and incinerators.

It finds its application in the field of nuclear power plants, aerospace, and defense as well.