Dust Cover Welding Machine

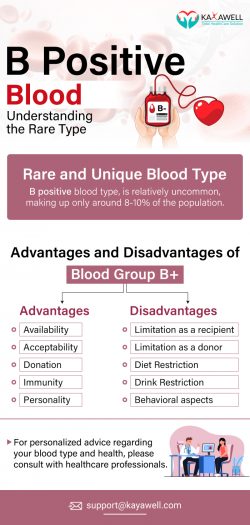

DUST COVER WELDING MACHINE

The equipment is a special welding equipment designed for the brake dust cover. It can be done manually only by installing the product.The equipment adopts two 250 gas shielded welding machines from Japan’s Panasonic brand. The welding machine has the function of timed spot welding, which ensures 100% of the size of the welding spot, and has very little welding spatter.

DUST COVER WELDING MACHINE PROVIDED BY XIHE

AUTOMATIC WELDING MACHINE FOR DUST COVER OF AUTOMOBILE BRAKE

The equipment is a special welding equipment designed for the brake dust cover. The equipment adopts two 250 gas shielded welding machines from Japan’s Panasonic brand. The welding machine has the function of timed spot welding, which ensures 100% of the size of the welding spot, and has very little welding spatter. It can be done manually only by installing the product.

THE PARAMETER OF AUTOMATIC WELDING MACHINE FOR DUST COVER OF AUTOMOBILE BRAKE

Input voltage

Enter the frequency

Rated total power

Clamping method

Product diameter

Strip thickness

Hydraulic power

Gas welding machine

Dimensions

3*380V

50HZ

26KW

Hydraulic

<φ380mm

<15mm

2.2KW

2 sets

2000*1700*1900mm

The Application Of Automatic Welding Machine For Dust Cover Of Automobile Brake

The equipment is mainly applied to the welding equipment of the dust cover of the brake. The equipment is designed with two stations, which can weld the same model of products at the same time, and can also weld two different models of products. Conduct continuous spot welding on the brake dust cover through the gas shielded welding machine to ensure that the size of the welding points is exactly the same and there is little welding spatter. The equipment adopts a fully sealed structure to reduce the damage of splash to human body.

The Advantages Of Automatic welding machine for dust cover of automobile brake

Automatically unload the material to the waiting tray, enter the hydraulic cutting device through the servo drive and automatically fall into the storage table. The length of the material is modified and stored through the color touch screen, and has the function of quantitative production to reduce unnecessary waste. When one of the stations has been loaded with products for automatic welding, the operator can load and unload products from the other station, which greatly improves the production efficiency.