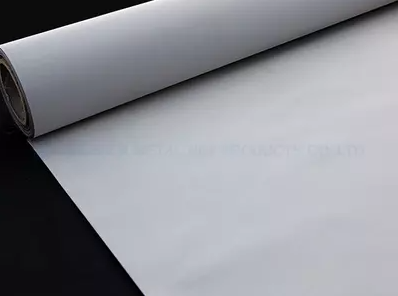

Dutch Weave Mesh

The dutch weave mesh is formed by weaving a limited number of warp threads to closely weave the largest number of weft threads together, resulting in a cloth that does not have holes that are easy to see. Dutch weave mesh is strong, stable, easy to clean and has a high flow rate, suitable for high-pressure liquid/solid separation.

Dutch weave mesh product information

The dutch weave mesh is formed by weaving a limited number of warp threads to closely weave the largest number of weft threads together, resulting in a cloth that does not have holes that are easy to see. Dutch weave mesh is strong, stable, easy to clean and has a high flow rate, suitable for high-pressure liquid/solid separation.

Max width for dutch weave mesh:

3 Meters which is unique mesh dimension for such fine mesh in woven mesh industry in China; Available stock for 2.5-3m are 2 micron and 5micron.

Material:

Normally it is 304, 201 material can be customized.

Size:

100mm, 127mm, 150mm, 156mm, 165mm in width; 10m and 20m in length.

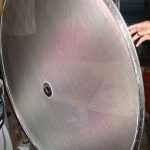

High Tensile warp wire configurations, a part of Auto Screen Changers used in the plastic extrusion industries.

Types of dutch weave mesh

Dutch weave mesh is divided into ordinary plain dutch weave mesh and twill dutch weave mesh, the difference is as follows

Plain Dutch Weave Mesh Pattern:

In a plain dutch weave mesh the diameter of the warp wire is larger than the weft. The mesh is formed by weaving a limited number of warps with the maximum number of weft wires woven tightly together, producing a cloth with no readily visible apertures. This mesh is strong and stable, easy to clean and with a good flow rate suitable for high-pressure liquid / solid separation.

The advantages of plain dutch weave mesh over plain weave mesh

● Higher mechanical stability.

● A finer opening can improve filtration efficiency and quality.

● Thicker wires have higher tensile strength.

Twill Dutch Weave Mesh Pattern:

Twill dutch weave mesh is produced with the weft wires packed together in the same principle as Plain Dutch Weave but with double the number of weft wires woven in an over two, under two pattern. The weft wires overlie each other creating a sinuous path of filtration. The cloth is very robust with a smooth surface and the finer weft wires and smaller pore sizes provide excellent flow characteristics. The finest filtration rates are obtained with this type of weave.

Manufactured as a Reverse Plain Dutch Weave in a twill pattern, which reduces the deformation of the warp wire, this cloth is very stable and particularly strong in the warp direction with a high flow rate.

Advantages of twill dutch weave mesh over twill weave mesh

● Better filtering performance.

● Higher tensile strength.

● It can be used to filter ultra-fine products.

● More stable structure.

Dutch weave mesh application

Dutch woven wire mesh is mainly used for filtration. It provides excellent filtering capabilities for a wide range of applications.

○ Petrochemical.

○ Pharmaceuticals.

○ Mining industry.

○ Waste water.

Special characteristics:

High Tensile warp wire configurations, a part of Auto Screen Changers used in the plastic extrusion industries.

· High Tensile Warp AISI 304 wire for Auto-Screen changers used in the Poly Extrusion Industry. The AISI 304 Warp Wire’s Tensile is 1300Mpa-1600Mpa.

· High Tensile Warp Copper Coated Carbon Steel wire for Auto-Screen Changers used in Plastic and Rubber Extrusion industry. The Copper coated Carbon Steel Warp wire’s tensile is 1500Mpa -2000Mpa.

· Rubbed Edges after slitting to help with tracking for Auto-Screen changers.

Specification of plain dutch weave mesh

Plain Dutch Weave Spec.

Warp Count

Weft Count

Warp Wire (mm)

Weft Wire (mm)

Norminal (micron)

Absolute Range

8

85

0.43

0.32

250

225-260

12

64

0.58

0.4

300

260-280

12

72

0.4

0.38

300

260-280

16

80

0.43

0.34

200

210-230

24

110

0.355

0.25

120

112-125

30

150

0.23

0.18

90

90-105

40

200

0.18

0.14

70

70-75

50

250

0.14

0.114

60

56-63

80

400

0.125

0.071

40

40-45

Specification of twill dutch weave mesh

Twill Dutch Weave Spec.

Warp Count

Weft Count

Warp Wire (mm)

Weft Wire (mm)

Norminal (micron)

Absolute Range

80

700

0.1

0.077

25

34-36

165

800

0.1

0.077

15

24-28

165

1400

0.068

0.04

10

15-18

200

1400

0.068

0.04

5

11-13

325

2300

0.036

0.025

2

7-8

Specification of reverse dutch weave mesh

Reverse Dutch Weave Stock

Weave Type

Mesh

Nominal Micron

RDTW

48/10

400

RDTW

72/15

300

RDTW

132/14

220

RDTW

132/17

175

RDTW

152/24

120

RDTW

250/40

90

RDTW

338/37

55

RDPW

180/120

75

RDPW

400/125

40

RDPW

600/125

28

Dutch weave mesh manufacturer

Milesen Steel Internet Products Co., Ltd as a professional dutch weave mesh manufacturer produces a wide range of custom dutch weave mesh to meet the filtration needs of our customers. Dutch weave filter mesh provides superior filtration capabilities for a wide range of applications including pressure, fuel and liquid filters for the aerospace, petrochemical, pharmaceutical, mining and wastewater treatment industries.