Frequency Inverter Meets Your Needs

As a professional frequency inverter supplier, our company takes quality as its premise and produces general inverters, solar inverters, and other main products, as well as inverter parts, reactors, filters, and a series of related products. Our inverters not only support single phase or three phase input but also have a wide range of wattage. It minimum kilowatt rating is 0.75 kw, and its maximum kilowatt rating is 800 kw. There are two types of it: 220v and 380v, and it is extensively employed in industry, agriculture, and daily life.

Our company has been established for 10 years, and thanks to our high quality, our products have a great competitive advantage in the frequency converter industry. The technical procedures for our drives are written by a team of top senior engineers with more than 40 protection procedures. Our products use imported chips, good-brand modules, large radiators, and a variety of high-quality materials to ensure the stable operation of the inverter and high efficiency output. We have rich experience in the production of variable frequency inverters and can provide customers with a range of customized services.

Types of Anchuan Frequency Inverters

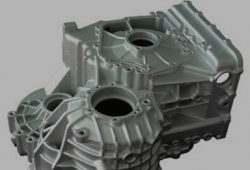

Important Components of Frequency Inverters

Frequency Inverters vs Traditional Motor Control MethodsFrequency Inverters vs Traditional Motor Control Methods

Frequency inverters, also known as variable frequency drives (VFD), have revolutionized motor control methods and offer several advantages over traditional control methods.

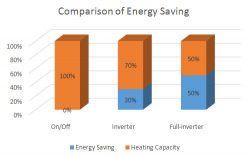

One key difference is that traditional methods, such as on/off control or direct-on-line (DOL) starters, provide only fixed-speed operation. In contrast, frequency inverters provide variable-speed control, allowing for precise motor speed regulation. This flexibility offers several benefits, including improved motor efficiency, reduced energy consumption, and enhanced process control.

Frequency inverters achieve variable-speed control by adjusting the frequency of the electrical input to the motor, which in turn adjusts the motor’s rotational speed. This allows the motor to operate only at the speed required for the particular load or application, eliminating the energy wastage associated with running at full speed constantly.

Furthermore, frequency inverters offer smooth and gradual motor acceleration and deceleration, reducing mechanical stress on the motor and associated equipment. This can extend the lifespan of the motor and reduce maintenance costs.

Traditional motor control methods also lack advanced protection features found in frequency inverters. Frequency inverters often include built-in overload protection, short-circuit protection, and phase loss detection. These safety features contribute to increased system reliability and offer greater protection against motor damage or failure.

Additionally, frequency inverters provide advanced control features such as torque control, position control, and sensorless vector control. These capabilities enable precise control over motor operations, allowing for optimized performance and enhanced process efficiency.

In summary, frequency inverters offer significant advantages over traditional motor control methods. They provide variable-speed control, increased energy efficiency, improved motor protection, and advanced control features. As a result, frequency inverters have become the preferred choice for motor control in a wide range of industrial applications.