FUNCTIONAL MASTERBATCH

Functional masterbatches are high-performance additives utilized in the plastics industry designed to enhance or modify certain physical and chemical properties of plastics. Common types of functional masterbatches include UV stabilizers, flame retardants, antistatic agents, and antioxidant masterbatches among others.

TYPES OF FUNCTIONAL MASTERBATCHES

Softening Masterbatch

Softening masterbatch can be combined with color and other additives to meet your requirements.

Antimicrobial Masterbatch

Antimicrobial masterbatches is commonly used in applications that require a high level of hygiene

Hydrophilic Masterbatch

Hydrophilic masterbatch is non-toxic, harmless, eco-friendly, with excellent water absorption and retention properties.

Anti-static Masterbatch

Anti-static Masterbatches reduces the accumulation of dust that keep the film’s appearance clean and clear.

UV Stabilizer/Absorb Masterbatch

UV stabilizer masterbatch offers superior protection against acidic substances such as pesticides and acid rain.

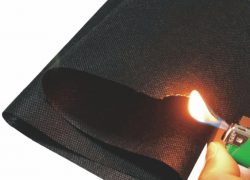

Flame Retardant Masterbatch

Application: part thickness, and desired flame retardant effectiveness all influence the amount of addition.

Fragrance Masterbatch

It is designed to enhance the sensory experience of various products by incorporating food-grade fragrances.

Cooling Masterbatch

Cooling masterbatches can extend the lifespan of equipment by reducing wear and tear caused by high temperatures.

Electret Masterbatch

Electret Masterbatches are used in the production of products in various fields such as electrostatic spinning, electrostatic dust removal, and air filtration.

Antiblock Masterbatch

Antiblock Masterbatch is used to enhance the surface properties of plastic film.

READ MORE

Slip Masterbatch

Slip Masterbatch

A slip masterbatch is used in the film industry to enhance the slip characteristics of plastic films.

PPA Masterbatch

Add Ratio: 1.0% or depend on desired performance.

Clarify Masterbatch

Clarify masterbatch enhances the heat resistance and rigidity of the product, ensuring it is safe for food contact.

Nucleating Masterbatch

Add Ratio: 1%-3% or depend on desired performance.

Antifog Masterbatch

Antifog Masterbatches is food grade which is used in food packaging industry.

Cold-resistant and Toughening Masterbatch

Cold-resistant and Toughening additive masterbatch has good compatibility without affecting transparency of the product.

Conductive Masterbatch

It is a type of plastic additive used to impart electrical conductivity to plastic products.

What Are the Features of Functional Masterbatches?

The features of functional masterbatches will vary depending on the type of masterbatch used. However, typical features may include improved durability, increased UV or heat resistance, enhanced flame retardancy, antimicrobial or antistatic properties, and improved slip or processing characteristics. These features can help enhance the performance and value of plastic products.

In What Industries Are Functional Masterbatches Commonly Used?

Functional masterbatches are commonly used in various industries, including construction, packaging, automotive, electronics, medical, and more to improve the properties and durability of plastic materials. The construction industry uses functional masterbatches to improve the weatherability, flame retardancy, and UV stability of plastic building materials, while the packaging industry can use functional masterbatches to extend the shelf life and appearance of food products. The automotive industry may use functional masterbatches to improve the mechanical properties of plastic parts, and the medical industry may opt for functional masterbatches that are antimicrobial or have pharmaceutical properties.

Can Functional Masterbatches Be Used in Food Contact Materials?

Yes, functional masterbatches can be used in food contact materials. However, they must meet the applicable regulations and requirements regarding food contact materials, such as those set out by the FDA and EU regulations. The masterbatch must be proven to be safe for contact with food and not cause any harm to human health.

Can Functional Masterbatches Improve Processing Efficiency?

Yes, functional masterbatches can improve processing efficiency by a variety of ways. Some functional masterbatches improve the slip and anti-blocking properties of plastic materials, making them easier to process, others provide better antistatic characteristics, reducing the accumulation of dust or static charge during the manufacturing process, and some others help in improving the processing rates and reducing the production costs.