FILM MASTERBATCH

Film masterbatch is a type of color masterbatch that is used to add color to plastic films in a variety of industries, including packaging, agriculture, and construction. It is typically composed of high-quality pigments and carrier resins that are dispersed evenly throughout the plastic film during the extrusion process.

TYPES OF FILM MASTERBATCH

Anti-static Masterbatch

Anti-static Masterbatches reduces the accumulation of dust that keep the film’s appearance clean and clear.

Antiblock Masterbatch

Antiblock Masterbatch is used to enhance the surface properties of plastic film.

Slip Masterbatch

A slip masterbatch is used in the film industry to enhance the slip characteristics of plastic films.

PPA Masterbatch

Add Ratio: 1.0% or depend on desired performance.

Laminating Modified Polyolefin

Laminating Modified Polyolefin has excellent dispersion and stable melt flow rate.

How Is Film Masterbatch Added to Plastic Film?

Film masterbatch is added to plastic film through a process called extrusion. The masterbatch is first mixed with the plastic resin pellets and then melted together in an extruder. The molten mixture is then passed through a die to form a thin film, which is then cooled and wound onto a roll.

WHAT TYPES OF FILMS ARE PRODUCED WITH FILM MASTERBATCH?

What Types of Films Are Produced with Film Masterbatch?

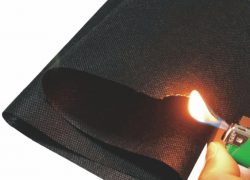

Film masterbatch is used to produce a wide range of plastic films, including packaging films, agricultural films, construction films, and industrial films. These films can have various properties such as UV resistance, antistatic properties, antimicrobial properties, and flame retardance, among others, depending on the type of masterbatch used.

WHAT IS THE SHELF LIFE OF FILM MASTERBATCH?

What Is the Shelf Life of Film Masterbatch?

The shelf life of film masterbatch depends on the type of masterbatch and the storage conditions. Typically, most film masterbatch has a shelf life of 12 to 24 months when stored in a cool, dry, and well-ventilated area, away from direct sunlight, heat, and moisture, and in its original packaging.

WHAT ARE THE CONSIDERATIONS FOR CHOOSING A FILM MASTERBATCH?

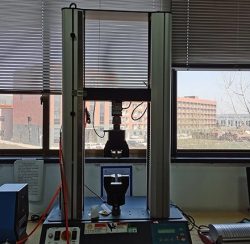

What Are the Considerations for Choosing a Film Masterbatch?

When choosing a film masterbatch, considerations include the type of polymer used in the film, desired properties of the film, such as color or additives, processing conditions, and end-use application requirements, such as durability or barrier properties. It’s also important to consider the compatibility and dispersibility of the masterbatch with the polymer.