HSG Engineering Hydraulic Cylinders

What is HSG Engineering Hydraulic Cylinder?

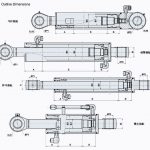

HSG type engineering hydraulic cylinder is a double-acting single-rod piston type hydraulic cylinder. It has the characteristics of simple structure, reliable operation, convenient assembly and disassembly, easy maintenance, buffering device and various connection methods. Mainly used in construction machinery, transportation, ships, lifting machinery, mining, machinery.

Advantages of HSG Engineering Hydraulic Cylinder:

The HSG series engineering hydraulic cylinder is a double-acting single-piston rod hydraulic cylinder; the mounting method is mostly ear-ring type. There are three types of external connection: internal key connection and flange connection according to the connection method of the cylinder head and the cylinder. Engineering hydraulic cylinders are mainly used in hydraulic systems such as construction machinery, heavy machinery, lifting machinery and mining machinery.

Product Description

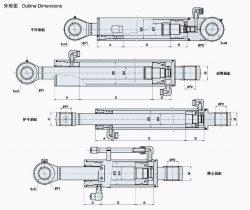

Front and Rear Earrings Installation Features of HSG Engineering Hydraulic Cylinder

The tail single earring is suitable for the single earring installation condition required for the path condition or structural design of the piston rod to be along the path of the same motion plane when the piston rod is moving along the same motion plane; It is possible to install the tail and rod end spherical bearings at this time, but pay attention to the pressure load that the spherical bearing is allowed to bear.

HSG double-acting single-rod piston type hydraulic cylinder is mainly composed of a cylinder tube, a piston, a piston rod, a cylinder head, a cylinder bottom, a piston rod head and related auxiliary devices. The piston divides the cylinder into two left and right chambers. By means of the action of the pressure oil, the cylinder reciprocates. In order to improve its working effect, a sealing ring is arranged on the piston to eliminate internal leakage. Where the piston rod passes through the cylinder head, due to the existence of the gap, the external leakage phenomenon is easy to occur, and the dust can enter the cylinder through the gap, so the sealing device and the dustproof factor are set. At the same time, in order to eliminate the influence of the eccentric load on the piston operation All hydraulic cylinders must be placed at the protruding end of the piston rod, and a guiding sleeve of a considerable length is provided. In addition, when the piston moves at a faster speed, the mechanical collision between the piston and the cylinder bottom and the cylinder head is serious, so the hydraulic cylinder at both ends, a buffer reduction gear should be provided.

Model Coding:

Engineering_Hydraulic_Cylinders_Model_Coding.jpg

① Unit code

②Connecting type L: Screw K: Clasp F: Flange

③ Bore/Rod (mm)

④ Pressure E: 16MPa F: 20MPa G: 25MPa

⑤ Mounting

⑥ Connecting in rod

⑦ Oil port 1: Screw 2: Flange

⑧ Stroke (mm)

⑨ Mounting distance

Technical Specification:

Specifications: Mark* is for speed ratio 1.64 only.

Bore D

Φ

d

d1

R

b

L6

M2

L10

L5

L7

L2

2-M1

H1

Φ1

pressure

speed ratio

16

20

25

1.33

1.46

2(1.64)

32

42

48

16

18

*20

16/GE6ES

20

18

20

M14X1.5

40

40

50

245

M14X1.5

15

50

40

50

56

20

22

25

20/GE20ES

25

30

M16X1.6

50

30

65

255

65

50

65

68

25

28

32

30/GE30ES

35

40

M22X1.7

60

40

280

M18X1.5

75

63

78

80

83

32

35

45

M27X1.8

65

295

79

80

95

102

40

45

55

40/GE40ES

45

50

M33X1.9

80

50

70

347

M22X1.5

18

110

90

108

114

45

50

63

M36X2

90

66

357

100

118

127

50

55

70

50/GE50ES

60

65

M42X2

110

60

72

402

M27X2

20

110

130

133

140

55

63

80

M48X2

115

77

422

125

145

152

63

70

90

M52X2

140

78

452

140

164

168

70

80

100

60/GE60ES

70

75

M60X2

155

70

85

498

150

180

75

85

105

M64X2

160

75

92

513

M33X2

22

160

194

80

90

110

M68X2

170

80

100

533

180

219

90

100

125

70/GE70ES

80

85

M76X2

190

89

107

588

M42X2

24

200

245

100

110

140

80/GE80ES

95

90

95

M85X2

210

100

110

628

220

273

110

125

160

90/GE90ES

105

100

105

M95X2

220

110

120

658

25

250

299

125

140

180

100/GE100ES

120

110

120

M105X2

255

122

135

688

Bore D

rod

pressure 16Mpa

speed ratio

Pushing force(KN)

pull force(KN)

1.33

1.46

2(1.64)

speed ratio=1.33

speed ratio=1.46

speed ratio=2(1.64)

32

16

18

*20

12.9

9.0

8.8

*7.8

40

20

22

25

20.1

15.1

14.0

12.3

50

25

28

32

31.4

23.6

21.6

18.5

63

32

35

45

49.9

34.5

34.5

24.4

80

40

45

55

80.4

55.0

55.0

42.4

90

45

50

63

101.8

70.4

70.4

51.9

100

50

55

70

125.7

87.7

87.7

64.1

110

55

63

80

152.1

102.2

102.2

71.6

125

63

70

90

196.4

134.8

134.8

94.6

140

70

80

100

246.3

165.9

165.9

120.6

150

75

85

105

282.7

191.9

191.9

144.2

160

80

90

110

321.7

219.9

219.9

169.7

180

90

100

124

407.2

281.5

281.5

210.8

200

100

110

140

502.7

350.6

350.6

256.4

220

110

125

160

608.2

411.9

411.9

286.5

250

125

140

180

785.4

539.1

539.1

378.3

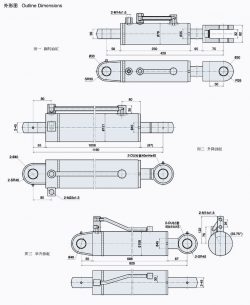

Mounting

Code

Mounting

Notice

1

single articulated clevis( with bush)

2

single articulated clevis( with oscillating bearing)

3

middle trunnion

Bore ≥80

4

front flange

Bore ≥80

5

middle flange

Bore ≥80

Piston rod connecting

Code

Mounting

Notice

1

outside screw

2

outside screw and articulated clevis( with bush)

3

outside screw and articulated clevis( with oscillating bearing)

4

one piece single articulated clevis( with bush)

5

one piece single articulated clevis( with oscillating bearing)

Specifications:

Mark* is for speed ratio 1.64 only.

Bore D

Φ

d

d1

R

b

L6

M2

L10

L5

L7

L2

2-M1

H1

Φ1

pressure

speed ratio

16

20

25

1.33

1.46

2(1.64)

32

42

48

16

18

*20

16/GE6ES

20

18

20

M14X1.5

40

40

50

245

M14X1.5

15

50

40

50

56

20

22

25

20/GE20ES

25

30

M16X1.6

50

30

65

255

65

50

65

68

25

28

32

30/GE30ES

35

40

M22X1.7

60

40

280

M18X1.5

75

63

78

80

83

32

35

45

M27X1.8

65

295

79

80

95

102

40

45

55

40/GE40ES

45

50

M33X1.9

80

50

70

347

M22X1.5

18

110

90

108

114

45

50

63

M36X2

90

66

357

100

118

127

50

55

70

50/GE50ES

60

65

M42X2

110

60

72

402

M27X2

20

110

130

133

140

55

63

80

M48X2

115

77

422

125

145

152

63

70

90

M52X2

140

78

452

140

164

168

70

80

100

60/GE60ES

70

75

M60X2

155

70

85

498

150

180

75

85

105

M64X2

160

75

92

513

M33X2

22

160

194

80

90

110

M68X2

170

80

100

533

180

219

90

100

125

70/GE70ES

80

85

M76X2

190

89

107

588

M42X2

24

200

245

100

110

140

80/GE80ES

95

90

95

M85X2

210

100

110

628

220

273

110

125

160

90/GE90ES

105

100

105

M95X2

220

110

120

658

25

250

299

125

140

180

100/GE100ES

120

110

120

M105X2

255

122

135

688

Bore D

rod

pressure 16Mpa

speed ratio

Pushing force(KN)

pull force(KN)

1.33

1.46

2(1.64)

speed ratio=1.33

speed ratio=1.46

speed ratio=2(1.64)

32

16

18

*20

12.9

9.0

8.8

*7.8

40

20

22

25

20.1

15.1

14.0

12.3

50

25

28

32

31.4

23.6

21.6

18.5

63

32

35

45

49.9

34.5

34.5

24.4

80

40

45

55

80.4

55.0

55.0

42.4

90

45

50

63

101.8

70.4

70.4

51.9

100

50

55

70

125.7

87.7

87.7

64.1

110

55

63

80

152.1

102.2

102.2

71.6

125

63

70

90

196.4

134.8

134.8

94.6

140

70

80

100

246.3

165.9

165.9

120.6

150

75

85

105

282.7

191.9

191.9

144.2

160

80

90

110

321.7

219.9

219.9

169.7

180

90

100

124

407.2

281.5

281.5

210.8

200

100

110

140

502.7

350.6

350.6

256.4

220

110

125

160

608.2

411.9

411.9

286.5

250

125

140

180

785.4

539.1

539.1

378.3

Mounting

Code

Mounting

Notice

1

single articulated clevis( with bush)

2

single articulated clevis( with oscillating bearing)

3

middle trunnion

Bore ≥80

4

front flange

Bore ≥80

5

middle flange

Bore ≥80

Piston rod connecting

Code

Mounting

Notice

1

outside screw

2

outside screw and articulated clevis( with bush)

3

outside screw and articulated clevis( with oscillating bearing)

4

one piece single articulated clevis( with bush)

5

one piece single articulated clevis( with oscillating bearing)

SIMILAR PRODUCTS