Hybrid Evaporative Cooler

A type of high-efficiency cooling device created and developed for the petrochemical sector by Longhua Technology Group (Luoyang) Company is the hybrid evaporative cooler. The high-efficiency cooler for the petrochemical industry has achieved an optimized combination of different cooling methods such as evaporative cooling, air cooling, and water cooling, thereby achieving a stable and reliable structure, extensive application scope, and obvious benefits such as energy saving, water saving, and environmental protection performance. This is based on the basic theories of latent heat exchange and sensible heat exchange.

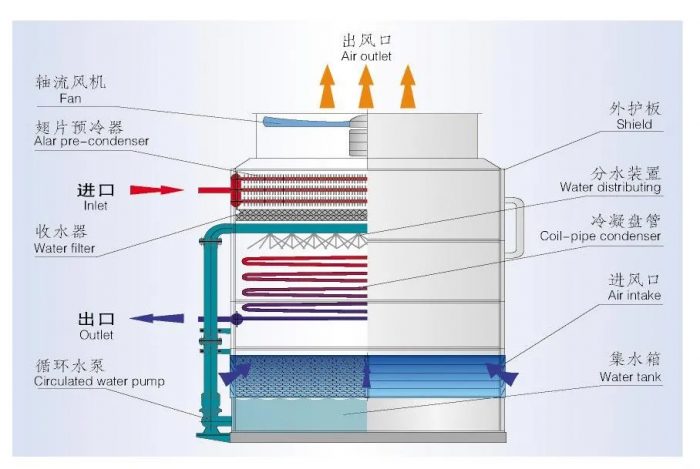

Hybrid Evaporative Cooler Operating Principle

The hybrid evaporative cooler is similar to the three-stage series cooling system of “air cooler + water cooler + cooling water tower” combined into one set of intensive equipment, but compared with the traditional series cooling system, it has significant “three reuse processes and three differences”:

1. “Three reuse processes” means that the wind and water are reused three times in the high-efficiency equipment. The first reuse of wind occurs from the lowest end of the evaporation tube to the liquid level of the water tank, in which the wind with the lowest temperature cools the circulating water falling continuously above to ensure that the water temperature in the water tank remains unchanged. The second reuse of wind occurs outside the water film of the evaporation tube, and the air with higher speed flows through the outside of the water film to form local negative pressure, which is beneficial to the evaporation of the water film and taking away the water vapor in time, thereby preventing the water vapor from forming pressure outside the water film. When the wind reaches the outside of the fin in the upward direction, the flow pattern changes from laminar flow to turbulent flow. In this state, the air heat transfer coefficient is high, the air temperature rises greatly (generally 10℃ – 15℃), and the high-temperature air is discharged from the induced-draft fan duct, thus completing the three-step cascade utilization of the air. The first cascade utilization of water also occurs at the bottom of the evaporation tube, in which water is in counter-current contact with the air inhaled from the outside for the first time. The water in torrential rain state has the function of washing, which can thoroughly flush the impurities in the air to the bottom of the water tank, ensure clean air passing through the tube bundle, and reduce scaling and blockage between the gaps of the tube bundle. The second reuse of water occurs outside the evaporation tube, and its main function is to evenly distribute the water film. It is necessary to ensure that each line of pipes and each row of pipes are evenly covered by the water film, without dry areas, and prevent scaling and corrosion under the scale. Most of the liquid water is intercepted by the water collector at the upper part of the spraying device. When saturated water vapor passes upward through the outside of the finned tube bundle, secondary interception occurs, in which saturated water vapor becomes unsaturated steam when passing through the superheated section of the fin and is discharged to the outside of the air duct, without the white mist phenomenon, and the air heat transfer coefficient outside the humidified fin is also be improved. In a series of cascade utilization, the water is reused three times, realizing “full use”.

2. “Three differences” means that the equipment is quite different from the traditional air cooler, water cooler and cooling water tower. The difference between the fin section of the equipment and the fin section of the air cooler is the difference in anticorrosion. The traditional air cooler generally operates in dry air environment, so the outer side of its aluminum fins basically does not need anticorrosion, but the fin outer side of the hybrid evaporative cooler operates in humid air environment, so the fin tube bundle needs to be anticorrosive as a whole, and the overall hot dip galvanized zinc anticorrosion is generally adopted on the processed steel pipe and steel sheet. The evaporation tube section of the equipment is also very different from the tube bundle of the water cooler. The cold medium of the water cooler generally goes through inside the tube and hot medium goes through outside the tube, but the hybrid evaporative cooler is just the opposite: The hot medium goes through inside the tube, the wind and water go through outside the tube, so the outer side of the tube also needs hot dip galvanized zinc anticorrosion. Hybrid evaporative cooler is also very different from cooling water tower. Traditional cooling water tower generally has packing, but hybrid evaporative cooler has no packing in the countercurrent contact section of wind and water. Besides, cooling water tower is generally installed on the ground, while hybrid evaporative cooler is a kind of movable equipment, which can be conveniently installed on pipe gallery, platform or roof, conducive to utilizing used equipment.