INDUSTRIAL AIR COOLING SYSTEM

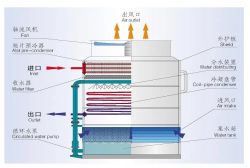

Industrial Air Cooling System is a type of cooling system that uses air as a medium to regulate the temperature of industrial processes and equipment. Industrial air cooling systems are used in a wide range of applications such as data centers, manufacturing facilities, and automotive plants. Unlike water-based cooling systems, air cooling systems use fans to circulate air and remove heat from industrial equipment. These types of air cooling systems can be more energy-efficient and easier to maintain than water-based systems, making them a popular choice for many industrial applications.

Industrial Air Cooling System Advantages

Energy Efficiency: Industrial air cooling systems are designed to be more energy-efficient compared to other cooling systems. This is because they use less power to cool the air, and they have a lower energy consumption for running compressors and fans.

Reduced Environmental Impact: Industrial air cooling systems often use refrigerants that have lower global warming potential and reduced ozone depletion potential, which makes them a more environmentally friendly option.

Reduced Operating Costs: The lower energy consumption of industrial air cooling systems translates to lower operating costs compared to other cooling systems. They have low installation and maintenance costs, making them an affordable solution.

Improved System Reliability and Performance: Industrial air cooling systems are more reliable and high-performing compared to traditional cooling systems. They can maintain a consistent temperature that meets the requirements of industrial processes, which helps to avoid damage to equipment and improve overall efficiency.

Lower Maintenance Requirements: Industrial air cooling systems usually have fewer moving parts than other cooling systems, which reduces the maintenance costs and requirements. Regular maintenance is still essential, but it is easier and more cost-effective to carry out.

Industrial Air Cooling Systems Maintenance

Regular cleaning of air filters to ensure proper airflow and prevent clogging.

Inspection and cleaning of evaporator and condenser coils to remove any accumulated dust or debris.

Lubrication of fan bearings and motors to ensure smooth operation.

Inspection of electrical connections, wires, and controls for damage or wear and tear.

Checking of refrigerant levels and ensuring there are no leaks.

Regular inspection of refrigerant lines for any damage or corrosion.

Cleaning and inspection of drain pans to prevent the buildup of algae and bacteria.

Inspection of ductwork and insulation to ensure proper airflow and prevent leaks or damage.

Difference Between Industrial Air Cooling System And Other Cooling Systems

Industrial air cooling systems are designed to handle the cooling needs of large industrial spaces such as factories, warehouses, and manufacturing plants. With air cooling technology, they are typically more powerful and efficient than other cooling systems, as they must be able to cool large volumes of air in a short amount of time.

Other cooling systems, such as residential air conditioning units or portable fans, are designed for smaller spaces and are not as powerful as industrial air cooling systems. In addition, industrial air cooling systems often use water as a cooling agent, while other cooling systems typically use refrigerants or other synthetic coolants.

Industrial air cooling systems are also designed to be more durable and long-lasting than other cooling systems, as they must be able to withstand the wear and tear of an industrial environment. They also need to be able to operate continuously for long periods of time without breaking down or overheating.

Overall, the main difference between industrial air cooling systems and other cooling systems is their size, power, efficiency, and durability, which enable them to handle the unique cooling needs of large industrial spaces.

Industrial Air Cooling Systems Troubleshooting

Start by checking the thermostat settings to ensure it is correctly set to the desired temperature.

Check the air filter for clogging that can lead to restricted airflow.

Verify that the tube bundles are clean and free of any debris.

Check the medium to verify that it is within manufacturer specifications.

Inspect the ductwork and look for any leaks or damage.

Check the electrical connections, wires, and controls for any damage or wear and tear.

Check the fan for damage.

If the system is still not working correctly, it’s recommended that a professional technician is called to perform a more in-depth diagnosis and repairs.