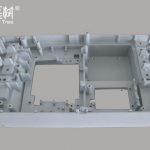

Motor Mold

The appearance and electrical performance of the product are guaranteed.

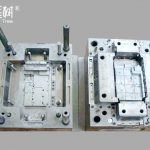

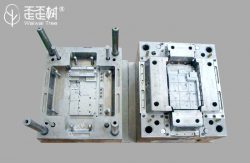

Mainly for injection molding, the design of the runner and the parting surface should be as small as possible, and the crossover, exit, protector and control board of the motor should not be damaged. Because BMC materials cannot be decomposed, we are the first in China without material handle structure. In addition, the inner hole of the motor can be without clearing material. Vacuuming structure, the mold temperature balance is consistent. The appearance and electrical performance of the product are guaranteed.

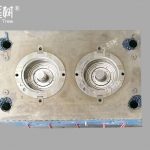

Motor Mold Design

Servo Motor Mold

BMC Plastic-Envelop Motor Mould

Over Mouding

BMC Rotor Mould

BMC Stator Mould

Air Conditioner Motor Mould

Refrigerator Motor Mould

Washing Machine Motor Mould

DC Motor Mold

AC Motor Mould

Automotive Motor Mould

Power/Electic Tool Rotor Mould

Hood Motor Mould

Motor End Cap Mould

Motor Bracket Mould

Motor Mold Supplier

Our motor molds cover a wide range, including: servo motor molds, plastic edging motor molds, plastic encapsulations molds, BMC rotor molds, BMC stator molds, air conditioner motor molds, refrigerator motor molds, washing machine motor molds, DC motor molds, AC motor molds, automotive motor molds, power tool rotor mold, range hood motor mold, motor end cover mold, motor bracket mold, etc.

Motor molds are widely applied. We provide a list of motor molds, including servo motor molds, plastic edging motor molds, plastic encapsulations molds, BMC rotor molds, BMC stator molds, air conditioner motor molds, refrigerator motor molds, washing machine motor molds, DC motor molds, AC motor molds, automotive motor molds, power tool rotor mold, range hood motor mold, motor end cover mold, motor bracket mold, etc. We have customized many types of motor molds for our customers according to their unique and specific requirements.

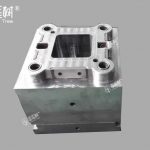

Motor Mold Specification

Model NO.

AB-3287

Mould Life

500000-1000000 shots

Certification

GBT19001-2016, ISO9001:2015

Warranty

1 Year

GBT-24001-2016

ISO14001:2015

Customized

Customized

Product Name

High Quality SMC Compression Cmposite Mould for Motor

Machine

Hydraulic Compression Machines

Cavity & Core Steel

SKD61, SKD11, H13, hardened P20

Surface Treatment

Highly polished and Surface crossing

Keyword

Motor Mold

Delivery Time

Within 45 Days After Payment

Service

Make product drawings and make molds.

Runner Information

No runner

Trademark

WAIWAITREE

Transport Package

Air Bubble Paper, Carton Boxes, Wooden Box

Specification

Customized

Origin

China

HS Code

8480719090

Factors Deciding the Quality of a Motor Mould

Maintenance cost and maintenance cycle

Quality of motor mold manufactured: dimensional stability, surface roughness, use ratio of product material

User friendliness, mould release and auxiliary time of production.

Damper Motor Internal Mould

Damper motor is responsible to direct and regulate airflow in zoning system. A functioning damper motor controls airflow of each area. We make customized damper motor internal mould to facilitate your damper motor production.