Shell Moulding

Shell Moulding Description

BMC/SMC shell moulding is mainly injection molded. The application of SMC in anti-explosion electric appliances change the dominance of steel and aluminium in anti-explosion solution. Compared with steel and aluminium materials, SMC has excellent performance in corrosion resistance, is lightweight, flexible and easy in engineering design. Its mechanical property is comparable to metal material. A series of advantages, like anti-static, heat stability and long service life can be obtained through adjusting SMC material.

PRODUCTS

Shell Moulding

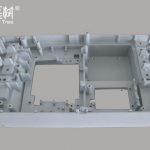

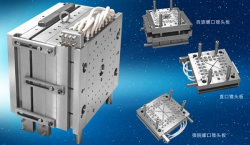

End Cap Mould

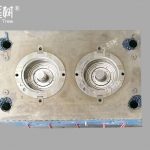

Lamp Housing Mould

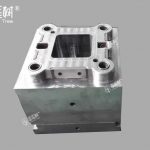

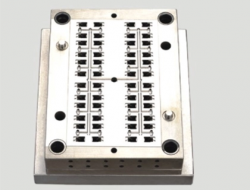

Circuit Breaker Housing Mould

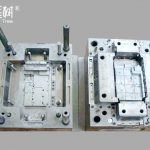

Housing Mould

Shell Moulding Manufacturer

Shell moulding include end cap mold, lamp housing mold, circuit breaker housing mold, cover mold. Light weight, high strength, precise size, high flatness, high insulation and high temperature resistance. The mold has a high degree of standardization, reasonable flow channel design, small cavity pressure, balanced temperature, no handle, and low power consumption.

Shell Moulding Applications

Including SMC/BMC electric switch box mold, SMC electrical wiring box mold, SMC/BMC instrument panel cover mold, etc.

Shell Moulding Products

Shell moulding we provide include end housing shell, Lighting shell, circuit breaker shell, enclosure shell. We provide end cap mould, lamp housing mould, circuit breaker mould and housing mould.

Why BMC is the most suitable material for loudspeaker?

BMC shell is a novel shell for loudspeaker, especially suitable for combination audio system. BMC shell has relatively high specific gravity and rigidity, performing higher sound effect than wooden ones. The higher the shell material density is, the louder the sound is, because BMC material reduces vibration produced by the speaker, particularly for loudspeaker with a high-power amplifier. BMC loudspeaker shell is able to deliver more original sound.