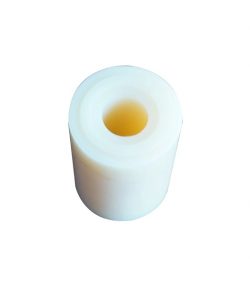

Nylon 66+GF30 3D Printing

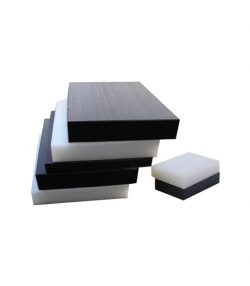

Nylon glass fiber is a kind of white powder, compared with ordinary plastic, its tensile strength, bending strength increased, thermal deformation temperature and material modulus increased, the thermal deformation and shrinkage of the material decreased, but the surface becomes rough, impact strength slightly reduced. The results show that the mechanical properties, dimensional stability, heat resistance and aging resistance of PA are improved obviously when 30% glass fiber is added to PA, and the fatigue strength is 2.5 times of that without. Nylon glass fiber materials are mainly used in automobile, home appliances and consumer electronics fields. The molding process of nylon glass fiber material is roughly the same as that of unreinforced nylon, but due to the increase of melt viscosity, the injection pressure and injection speed should be appropriately increased, and the temperature of barrel should be increased by 10°C~40C. During processing, the glass fiber will be oriented along the melt flow direction, thus enhancing the mechanical properties and dimensional stability of orientation direction.

3D Printed Nylon Glass Fiber Material Properties

3D printed nylon and glass fiber,PA3200GF(Nylon + glass fiber)

Glass fiber nylon powder PA3200 GF is a white, glass beaded poly amide 12 powder characterized by a combination of rigidity and good elongation at break.Glass fiber filled nylon powder (30% glass fiber), glass fiber filled PA12 nylon powder, white.

Print the advantage of Nylon 66 GF30 3d Printing

1. Parts used under high temperature conditions

2, Need to have high rigidity, high thermal deformation resistance

3, Need specific stiffness, high thermal deformation temperature and low

Nylon 66 GF30 3D Printing Material Properties

High rigidity, high wear resistance, high heat resistance

Good detail of parts, good geometric precision of parts, good surface quality, good post-processing performance of parts,

Long term performance.

1) High stiffness;

2) Wear resistance;

3) Improved temperature performance;

4) Good heat load capacity;

5) Good surface quality;

6) High dimensional accuracy and detail resolution;

7) Good processing;

Application at Function Rapid Prototype of Nylon 66 GF30 3D Printing

Engine parts (direct parts manufacturing), need to have high rigidity, high thermal deformation resistance of parts.

https://www.gjprototyping.com/nylon-66gf30-3d-printing-service/