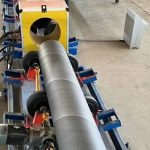

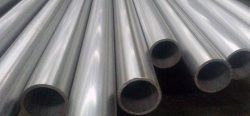

STAINLESS STEEL SPIRAL WELDED PIPE PRODUCTION LINE

The stainless steel spiral welded pipe unit adopts front-swing intermittent production, which is a complete set of spiral pipe welding machine integrating machinery, electrical automation control and hydraulic control.

SPECIFICATION OF STAINLESS STEEL SPIRAL WELDED PIPE PRODUCTION LINE

Forming direction

Front swing, intermittent production, center positioning

Forming direction

Left feed, right rotation molding

welding speed

0.5~2m/min

Forming method

Three-roll bending forming, external control roll sizing, internal expansion plate auxiliary forming

welding equipment

TIG welding machine WS1000

Welding method

Internal welding, argon arc automatic welding without filler wire

Host installed capacity

100 KVA

PRODUCT (STEEL PIPE) PRODUCTION PROCESS

Uncoiling→pinch leveling→vertical roller→shear butt welding→vertical roller→delivery machine→guide plate→forming→internal welding→flying cutting of centralizer→drawing out

STAINLESS STEEL SPIRAL WELDED PIPE PRODUCTION LINE EQUIPMENT COMPOSITION

Uncoiler

Pinch leveler

Electric vertical roller

Shear butt welding

Delivery machine

Guides

Forming machine

Front bridge

Rear bridge

Fly cutting car

Internal welding device

https://www.txhmachine.com/products/stainless-steel-spiral-welded-pipe-production-line.html