The Structure Design and Function of Cold Roll Forming Machine

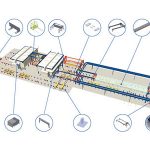

In order to meet the production requirements of different products, the cold roll forming machine is equipped with different combinations of cold-formed steel units, and each type of unit has its own applicable processing range. While mastering the knowledge, we also need to involve this one, so today Zhejiang Jinggong Science & Technology Co., Ltd. will introduce to you the layout and characteristics of the cold roll forming machine, which is convenient for everyone to use in the future.

1. The layout of the cold roll forming machine

The cold-formed steel unit and the other two types of units constitute the main production equipment for cold-formed steel, while the open cold-formed steel unit is mainly designed for non-welded cold-formed steel products, so there is no longitudinal welding equipment in the unit. In addition, the processes of uncoiling, strip butt welding, forming, online spot welding, straightening, cut to length, and collection can be completed on this unit.

At present, this type of unit is widely used in the industry. It has the ability to develop new products and is beneficial to the forming of the product on the cold roll forming machine. In addition, the drive mode of the open cold-formed steel unit can reduce power consumption and increase the surface quality of the steel, but it is a suitable forming unit for the product.

2. The characteristics of the cold roll forming machine

The feature of the cold roll forming machine is that the two cantilever rolling mills are installed relative to each other, but they have a common foundation and drive. This equipment can be used for narrow-side products or wide-side products away from the middle surface, and we also found that the width of the material is determined by the distance relative to the roll.