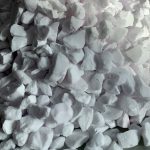

White Fused Alumina

White fused alumina is made of industrial alumina powder, which is smelted in an arc at a high temperature of over 2000 degrees and then cooled. It is suitable for the manufacture of ceramics, resin-bonded abrasive tools, grinding, polishing, sandblasting, precision casting etc.

Types of White Fused Alumina

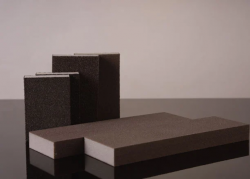

White Fused Alumina for Abrasive

White Fused Alumina for Refractory

Special Treated White Fused Alumina

White Fused Alumina Features

Characteristics

White fused alumina has the characteristics of moderate hardness, good self-sharpening, wear resistance and stable chemical properties. Suitable for abrasives, industrial chemicals and refractory materials.

High Purity

The higher the alumina content in white fused alumina, the better the purity and quality of the white fused alumina.

Good Corrosion Resistance and Wear Resistance

As an abrasive material, white fused alumina abrasive must have good corrosion resistance and wear resistance in order to become the basic material for abrasive blasting.

Moderate Hardness

White fused alumina has moderate hardness, good self-sharpening and good grinding ability, and is suitable for sandblasting.

Stable Chemical Properties

White fused alumina has good corrosion resistance and stable chemical properties. Also used as a refractory material. White fused alumina refractories are used for high temperature coatings, refractory bricks, furnace linings, etc. Widely used in steel, cement, ceramics, petrochemical and other industrial fields.

Faqs of White Fused Alumina

What is the difference between white and brown fused alumina?

Application: White fused alumina is used by the customers who are more pursuit of quality. It has a good polishing effect and is mostly used in carbon steel, alloy steel, malleable cast iron, hard bronze, etc. Brown fused alumina is widely used in the market.

Hardness: The hardness of white fused alumina is slightly higher than that of brown fused alumina.

Smelting: Brown fused alumina is made by melting bauxite at high temperature and is made by redox reaction. White fused alumina is made of high-quality alumina powder. Refining and crystallization of white fused alumina by electrofusion. High purity, good self-sharpening, acid and alkali resistance, corrosion resistance, high temperature resistance, stable thermal performance.

Purpose: White fused alumina: mostly used in high-end industries. It has a strong cutting force, is used to remove metal or non-metal burrs, has a polishing effect on the surface grinding of parts, and is a medium polishing abrasive.

Brown fused alumina: mostly for mass users, used to remove burrs on the surface of metal parts such as stainless steel, carbon steel and aluminum alloy.

Alumina content: white fused alumina: alumina content is 99.4%, Mohs hardness is 9.0. Brown fused alumina: alumina content of 95%, Mohs hardness of 8.9.

Color: white fused alumina: white and transparent. Brown fused alumina: brown-black, brown-red.

How is white Fused Alumina made?

White fused alumina is made from industrial alumina powder, which is smelted in an arc at a high temperature of more than 2000 degrees and then cooled. It is suitable for the manufacture of ceramics, resin-bonded abrasive tools, grinding, polishing, sandblasting, precision casting, etc. It can also be used to manufacture high-grade refractory materials. The code “WA” is consistent with international general standards and national standards.

Do you add boric acid during smelting?

No. In order to minimize the sodium content, we choose the low sodium alumina powder and increase the melting time.

What’s the sodium content of your white fused alumina?

Three kinds of white fused alumina are available:

White fused alumina with Na2O 0.2%

White fused alumina with Na2O 0.3%

White fused alumina with Na2O 0.4%