ASTM A350 LF2 Carbon Steel Slip On Flanges Exporters in India

Carbon steel A350 LF2 Flanges consist of 1% carbon and 1.65% manganese and other elements are present in quantities too small to affect its properties. Flange WN A350 LF2 is used extensively for the manufacture of flanges and fittings, has moderate strength and impact toughness, and applications that require cold temperature service where corrosion resistance is not essential.

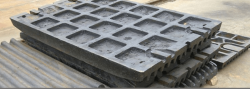

Flange material A350 LF2 is the standard specification for carbon steel and low alloy steel forged flanges and flanged fittings for low-temperature services. A350 lf2 Welding Neck Flange can be expert satisfactorily by using standard machine tool manufacturers with recommended feeds and speeds. They have very good machinability, dependent on condition, and operations such as turning, sawing, milling, broaching, etc. The rim has a series of drilled holes that allow the flange to be affixed to another flange with bolts. It consists of a circular fitting with an extending rim around the circumference. It is machined from forging, it is typically butt welded to a pipe.

ASME SA 350 LF2 Flanges forging temperature is 900 – 1200 °C. To avoid heavy scaling soak times should be kept to a minimum. But enough time should also be given to allow the center to achieve furnace temperature. After forging it should be allowed to cool in still air. Blind flange LF2 has the face thickness of a flange, a similar bolting pattern, and a matching face type. It is readily weldable by any technique. It is a flange that does not have a hub or a boring center. Pipe flange A350 LF2 is carbon steel usually supplied in the normalized, normalized, and tempered or quench and tempered condition.