Butyl Rubber

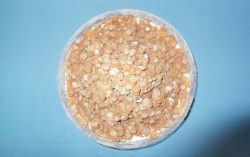

Butyl rubber is a synthetic elastomer made by combining isobutylene and isoprene. It is a white or off-white translucent elastomer with a density of 0.91~0.92g/cm. Butyl rubber has poor molecular chain flexibility and compact structure, and its air tightness is the first among rubbers. Butyl rubber has excellent heat resistance, weather resistance, ozone aging resistance and chemical corrosion resistance. Properly formulated butyl vulcanizate can be used for a long time at 150~170C, and the heat resistance limit can reach 200C. Butyl rubber products exposed to sunlight for a long time. And in the air, its performance changes very little, especially the anti-ozone aging performance is 10-20 times better than natural rubber. Butyl rubber has excellent resistance to acids, alkalis and redox solutions except for strong oxidizing concentrated acids, and it swells very little in polar solvents such as alcohols, ketones and esters. The above characteristics are determined by the extremely low degree of unsaturation, strong structural stability and non-polarity of butyl rubber.

There are many applications for butyl rubber, but this synthetic rubber is popular for some key products. Tire inner tubes, speakers, roofing, and gas masks are often made with butyl. Butyl is also used by the pharmaceutical and sporting industries.

Types of Butyl Rubber

Regular Butyl Rubber

Regular Butyl Rubber has superior air impermeability, outstanding performance of heat-resistance, chemical corrosion-resistance, thermal aging resistance, and good curing performance. it has high tensile strength and elongation at break, which is determined by the crystallinity of butyl rubber in the stretched state. This means that butyl vulcanizate has better strength even without carbon black reinforcement, so it can be used to make light-colored products.

Brominated Butyl Rubber

The chain molecules of butyl rubber are partially introduced with bromine and denatured. Vulcanization is fast, can be mixed with NR, SBR, etc., and has good adhesion to metals or other polymers.

Chlorinated Butyl Rubber

After chlorine is introduced, the vulcanization is rapid, and the compatibility with other rubbers is good The heat resistance of chlorinated butyl rubber is excellent. The ozone resistance and other characteristics comparable to those of Regular butyl Rubber is also good.

Advantages of Butyl Rubber

Butyl rubber is a common elastomer that has been in commercial use since the 1940s. The ability for butyl to retain air and its flex properties made it ideal for tire inner tubes as its first major application.

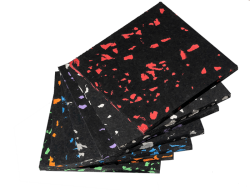

Butyl rubber is heavily resistant to gas and moisture permeation. It is also resistant to oxygenated solvents, alkalis, flexing, and abrasion, making it favorable for certain applications. Butyl rubbers can provide high energy absorption and electrical isolation performance as well.

Butyl rubber is also highly resistant to sunlight, ozone, heat aging, animal and vegetable oils, ammonia, and countless other chemicals. The molecular structure of butyl can even be oriented to resist stress.

What Is Butyl Rubber Used For?

Based on that Butyl rubber has poor molecular chain flexibility and compact structure, and its excellent air tightness butyl rubber is an important material in the manufacturing of tubeless tires, inner tubes, sports-ball bladders, glove-box gloves, etc.

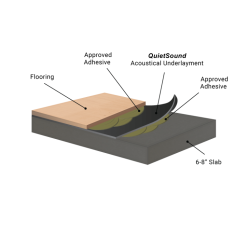

As a waterproofing material, it is applied as a liner in tanks and ponds. It is used as a patching material for membrane roofs and as a sealant for insulated windows.

As a vibration dampener, butyl rubber is used for shock mounts, suspension bushings, and car- and truck-body mounts. Speaker cone edges are often made from butyl rubber today where once they were commonly made of foam. Stoppers for labware and medical equipment are manufactured from the material. Owing to its low permeability, it is also used in making gas masks. Butyl rubber is flexible enough that it can achieve a good face seal.

Butyl synthetic rubber, in its food-grade form, is used to make chewing gum. It has all but replaced the gum of the Chicle tree except in a few specialty, natural products. There have been some efforts to collect used chewing gum and recycle it into new products. Improper disposal of chewing gum is a chronic urban blight.