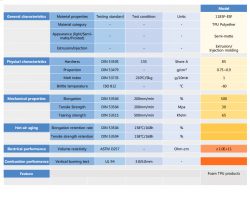

Rubber-coated Metal Material (RCM)

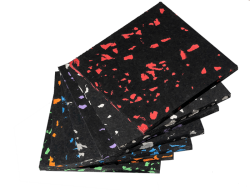

Teamful sealing rubber coated metal material applied uniformly rubber coating on the surface of base metal steel through a specific production process. It has good heat resistance and long-term durability, as well as a very low compression permanent deformation rate. Compared with traditional non-metallic sealing materials, RCM China, RCM quality has relatively long service life, it is usually used in application for higher pressure, higher temperature and stricter sealing requirements.

Why Use Rubber-Coated Metal Material?

Metal rubber coating material is a high performance composite material, its advantages mainly include:

Adhesive integrity and durability: metal rubber coating material has good adhesive integrity, which can maintain long-term stability in various environments. At the same time, this material also has good durability, could withstand long-term use and the influence of various environmental factors.

Excellent bolt load retention performance: metal rubber coating material can maintain excellent load holding performance at the part of bolt connection, making the connection part more stable and reliable.

Dimensional stability: metal rubber coating material has good dimensional stability, which will not expand and contract with the change of temperature and humidity. This characteristic makes metal rubber coating material an ideal sealing material and shock absorbing material.

Easy to fit flange surface: metal rubber coating material can better fit the flange surface, reducing the processing cost. At the same time, the flexibility of this material is also better, which can adapt to various shapes and sizes of the flange surface.

In general, metal rubber coating material has good comprehensive performance, which can maintain good performance in various complex environments, and has a wide range of application prospects.

How Is Rubber-Coated Metal Maintained?

The storage requirements of rubber involved materials see belows,

Storage temperature: the optimal indoor storage temperature of rubber materials should be controlled between 15 °C and 25 °C. Need to avoid high or low temperature warehouse environment, which will lead to aging or solidification of rubber, affecting the quality of rubber.

Storage humidity: the storage humidity of rubber materials should be controlled between 60 – 70 percent. Avoid too high or too low humidity environment. If the humidity is too high, it may lead to rubber becoming sticky. If the humidity is too low, it will lead to brittle rubber materials.

Storage ventilation requirements: keep a good ventilation environment, avoid moisture and/or heat accumulation, in order to maintain the quality of rubber materials.

FAQS

FAQs of Rubber-Coated Metal?

How to choose rubber coating type?

According to the temperature of the application site and the type of sealing medium, the type of rubber coating is selected. The commonly used coatings are divided into fluorine rubber coating and NBR coating.

What are the characteristics of fluorine rubber?

What are the characteristics of NBR?

Can the laser cutting process be used for processing?