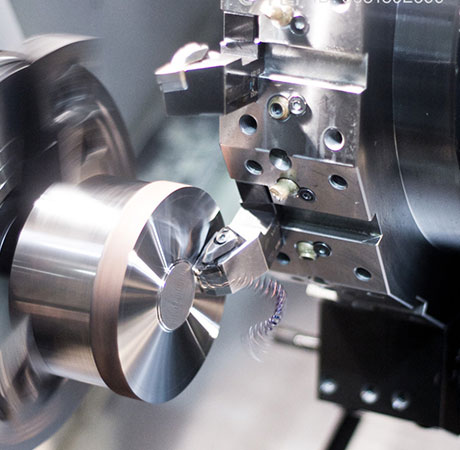

CNC Machining Processes

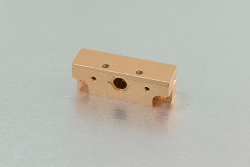

Sibai specializes in manufacturing precision machined parts for the medical, automotive, machines, research, and other industries. With over 20 years knowledge and experience, our team is able to produce parts that require innovative tooling and fixturing in a timely manner. We approach each job with the intention of minimizing the number of operations & run-time, therefore increasing accuracy & efficiency, and decreasing cost. We are capable of holding tight tolerances in difficult to machine materials such as copper, stainless steel, titanium, etc. CNC Machining uses a modern CAM system and highly precised machining and measuring equipment to ensure the highest quality products and to realise customer satisfaction.

Custom CNC Machining FAQ

How fast does Sibai provide samples?

Generally Sibai needs 3-6 work days to finish samples, from the order confirmation to delivery. If the material, cutting tools, and clamping tools and inspection tools are all ready, it needs only a half day or at most 3 days to finish samples.

What types of threading options in Sibai are available?

Sibai makes threads by the ways of thread lathe cutting, thread forming, dilling and tapping, thread rolling, thread die holder forming.

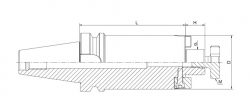

What is the maximum part size for Sibai CNC machining?

Sibai’s CNC machines can make the maximum size, 1500 x 800x 800mm.

Sibai’s CNC Lathes can make the maximum size Ø300 mm.

What is the most precise tolerance Sibai can make?

Sibai make the most precise tolerance +-0.001 mm.

How fast oceanshipping from Shenzhen China to Europe and the USA?

Generally it takes 7-10 days from goods picked up from Sibai’s warehouse to vessel despatch. It takes 28 days from Shenzhen port to Hamburg, and 35 days from Shenzhen to USA port.

https://www.sibaicnc.com/cnc-machining/