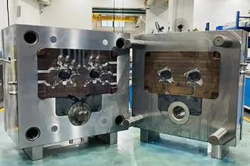

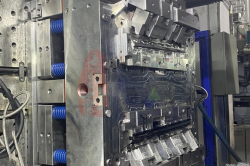

Medical Equipment Mold

Medical Equipment Mold

Proto-mold is Strictly in accordance with ISO 13485 international medical product standards for production and management. No matter mold development and production plan stand on the customer’s point of view of cost. Proto-mold will effectively control time and capital cost.

Medical Equipment Mold Material Properties

Medical Equipment Mold Materials Info

1

PE

Polyethylene (Polyethylene) is short for PE. It is a polymer organic compound made of ethylene. Polyethylene is recognized as the best material in the world for contact with food. Non-toxic, tasteless, odorless, in line with food packaging health standards. Polyethylene film, light and transparent, with moistureproof, oxygen resistance, acid resistance, alkali resistance, air tightness, excellent heat sealing properties. It is known as “plastic flower”. It is the most important material for plastic packaging printing.

2

PVC– Polyvinyl chloride

Polyvinyl chloride (PVC) for short, molecular formula (CH – CH) N, is the most important type of vinyl polymer, is the world’s second only to polyethylene plastic varieties. In the domestic production of plastic in the first place. In the printing industry, polyvinyl chloride color calendering film and transparent glazing film are often used to make books, folders, tickets and other covers of the packaging decoration.

3

Shrinkfilm– to shrink a thin film

Shrinkfilm, or Shrinkfilm, is a thermoplastic film that is stretched and directed during production and shrinks during use when exposed to hot air or infrared radiation. After heat treatment, the film is tightly wrapped on the packaging, the shrinkage force reaches the maximum in the cooling stage, and can be preserved for a long time.

4

LDPE– Low density polyethylene

Low density polyethylene, referred to as LDPE is the largest variety of plastic packaging and printing industry in the world. The specific gravity of 0.92~0.93, can float in water. Low crystallinity (60%), in the pressure of 1000~3000kg/C square meter body polymerization, so also known as high pressure polyethylene. At 23 degrees Celsius, the density is about 0.92. Poor calendering molding, suitable for blow molding process into tubular film. Suitable for food packaging, fiber products packaging, daily chemical products packaging.

5

HDPE– High density polyethylene

High density polyethylene, referred to as HDPE. The density is 0.941~0.965g/ cc. With low pressure polymerization, it is also known as low pressure polyethylene. Milky white, indicating poor luster. Film processing can be blow molding and T – die extrusion process. Heat resistance to cooking, cold resistance to freezing, moistureproof, air proof, good isolation performance, and not easy to damage, the strength of LDPE two times. Easy to open. Paper – like strong, known as “paper – like plastic film”.

6

BOPP– bi-directional stretch polypropylene film

Biaxial tensile polypropylene film, also known as biaxial tensile polypropylene film, English abbreviation code BOPP, is characterized by tensile molecular orientation, mechanical strength, folding strength, gas density, moisture barrier is better than ordinary plastic film. Compared with cellophane, the unit price is lower than cellophane. Due to the excellent transparency of this film, the color reproduction after printing is particularly bright and beautiful, which is an important base material of plastic composite flexible packaging.