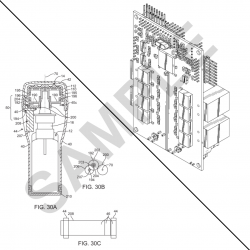

PCBs for Healthcare Device

Common Uses of PCBs in Healthcare Devices

1. Blackhead meter

PCB is used in the blackhead meter to control electronic components and control circuits to ensure the accuracy and stability of the device.

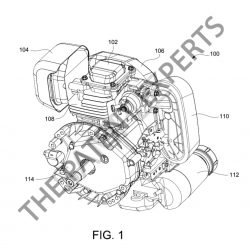

2. Oxygen injector

PCB is used as a circuit board in an oxygen injector to control various functions of the oxygen injector, such as oxygen concentration control, oxygen flow control, etc.

3. Hydration instrument

In the hydration instrument, PCB is used to control electronic components and control circuits to ensure the accuracy and stability of the equipment, as well as to control the work of the pump and the control of water temperature and other functions.

4.Facial Firming and Lifting Instrument

The facial firming and lifting instrument use PCBs to control electronic components and control circuits to ensure that the equipment can accurately control parameters such as frequency, power and time.

5. Moxibustion instrument

In the moxibustion instrument, PCBs are used to control parameters such as temperature, time and power to ensure the accuracy and stability of the device.

6. Eye massage instrument

In the eye massage instrument, PCB is used to control parameters such as vibration, temperature and time to ensure the accuracy and stability of the device.

7. Leg massager

In the leg massager, PCB is used to control the electronic components and control circuit of the massager to ensure the accuracy and stability of the device.

8. Waist massager

In the waist massager, PCBs are used to control the electronic components and control circuits to ensure that the equipment can accurately control parameters such as frequency, power and time.

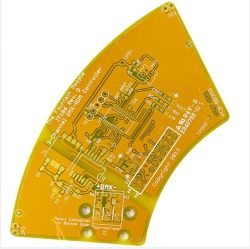

Advantages of Our PCBs for Healthcare Devices

First, PCBs have a wide range of applications in medical equipment, such as medical monitors, medical imaging equipment, electrocardiographs, surgical robots, etc. These devices need highly sophisticated electronic components and circuits, and our PCBs can provide high-precision components for these devices.

Second, PCBs can also help medical devices to achieve more accurate and efficient data acquisition and processing. For example, medical monitors need to collect data on patients’ vital signs in real time and analyze and process these data. Our PCBs can provide high-precision data acquisition and processing functions for these devices, thus improving the performance and efficiency of medical devices.

In addition, our products can also help medical devices achieve safer and more stable operations.