PCB Manufacturing Capabilities

The PCB manufacturing process consists of several stages. It starts with creating the PCB layout design on computer-aided design (CAD) software. The layout data is then converted into a photomask which is used to expose the copper on the PCB. The exposed copper is then etched away to form the traces and pads. After the etching process, the PCB goes through a drilling process to create holes for the components. A solder mask is then applied to the board to protect the copper traces and prevent shorts. The board is then coated with a layer of solder to facilitate the soldering of components. Finally, components are soldered onto the board and tested to make sure the PCB works properly.

Types of PCB Manufacturing Capabilities

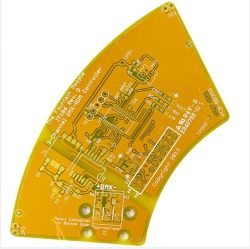

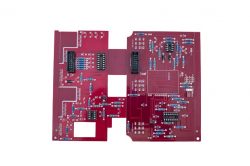

Rigid PCB Capabilities

Rigid PCB is rigid printed circuit board with electronic components mounted on the surface. They offer superior performance, higher density, and increased reliability compared to flex PCBs. Rigid PCBs are suitable for high-frequency, high-power, and high-speed applications and are used in many consumer products.

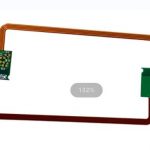

Flex PCB Capabilities

Flex PCBs are printed circuit boards with flexible materials that can bend, twist, and conform to various shapes. Flex circuit board offers high-density circuitry and reliable performance in small form factors. They are used in a wide range of applications, including medical, military, automotive, and consumer electronics.

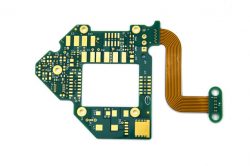

Rigid-Flex PCB Capabilities

Rigid-Flex PCBs combine the benefits of both rigid and flexible printed circuit boards in a single construction. Flexible rigid PCB enables complex circuit routing and miniaturization, allowing for improved reliability and performance in space-constrained applications.

Aluminum PCB Capabilities

Aluminum PCBs are high-performance circuit boards with excellent thermal conductivity, lightweight design, and excellent electrical insulation. They are ideal for LED lighting, power supplies, and automotive electronics.

Copper PCB Capabilities

Copper PCB is a printed aluminum circuit board that uses copper as its conductor instead of traditional aluminum. Copper PCBs allow for faster signal transmission, higher current capabilities, and enhanced durability.

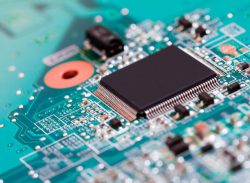

HDI PCB Capabilities

HDI PCBs are high-density interconnect printed circuit boards that allow for increased circuit density, higher signal integrity and improved heat dissipation. HDI PCB board is capable of providing up to 10x the number of connections in the same space as traditional PCBs.

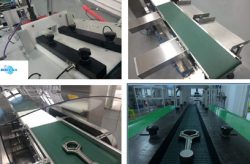

Quick Turn PCB Capabilities

Quick Turn PCB capabilities allow PCB manufacturers to produce printed circuit boards quickly and with high quality. Quick turn PCB uses advanced technologies such as machine automation, AI-driven design, and high-end materials to minimize production time while still providing quality products.

High-Frequency PCB Capabilities

High-Frequency PCBs are designed to carry signals at higher frequencies than standard PCBs. The high frequency circuit board is built with specialized materials to reduce signal loss and is optimized for signal integrity. They are used in applications such as communication systems, medical equipment, and aerospace.

What is the difference between PCB fabrication and PCB assembly processes?

PCB fabrication and assembly are two distinct steps in the process of creating a printed circuit board (PCB). PCB fabrication involves the production of the actual PCB, which includes etching the copper traces onto the board, drilling the holes, and applying the solder mask. PCB assembly involves the placement of components onto the board, as well as the soldering of components onto the board.

PCB fabrication is the first step in the PCB manufacturing process. This step involves the production of the physical PCB. The components used in the fabrication process are copper sheets, sheets of insulation, laminate material, and solder masks. The copper is etched to create the desired circuit patterns, holes are drilled for components to be mounted, and the solder mask is applied to protect the board from oxidation.

PCB assembly is the second step in the process and involves the placement of components onto the board and soldering of the components. In this step, components are placed onto the board and soldered in place. It is important to ensure that the components are correctly placed on the board and that the correct amount of solder is applied so as to ensure a strong and reliable connection.

In conclusion, PCB fabrication and PCB assembly are two distinct steps in the process of creating a printed circuit board.

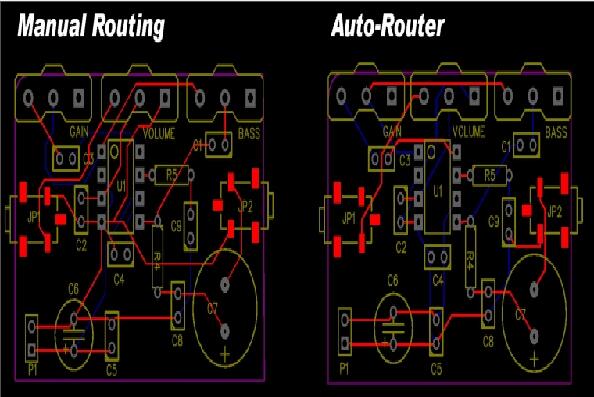

PCB Design/Layout

PCB layout and design is the process of creating a printed circuit board to meet specific requirements. It involves the placement of components, routing of signals, the creation of a board stickup.

Types of PCB Components Sourcing

PCB Components Sourcing

The Components Sourcing of PCB is a key part of the production of Printed Circuit Boards (PCBs). It is an important step to determine the quality and reliability of the assembled PCBs.

Types of PCB Capabilities

PCB Capabilities

PCB Manufacturing capabilities include design and fabrication of multi-layer printed circuit boards with a wide range of technologies, materials, and features.

Types of PCBA Capability

PCBA Capability

A printed circuit board (PCB) is a flat board that has circuitry printed on it, and is used to mechanically support and electrically connect electronic components.