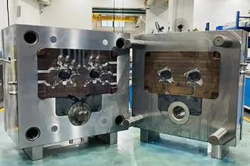

Plastic Injection Molding

Which Mold do you want to do? Plastic Injection/die casting or punch mold, etc. Which Mould Material do you want choice? 45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61, etc. Which does the Product Material want? PP, PC, PS, PE, PU, PVC, ABS, PMMA, etc.

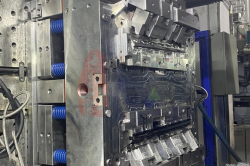

How many Cavities? Single/Multiple. Which Designing Software do you use? UG/CAD/PROE etc. Runner? Hot/cold.

Tolerance? 0.005 – 0.01mm. Mould Life? 300000 – 1000000 Shots. Mould Base? LKM/HASCO/DME, etc.

Package Wooden Case Delivery By Sea/By Air or keep the mold in our factory and injection from us. As per customers’ demand.

With plastic injection molding services, GreensTone is able to provide complete product manufacturing and fabrication for our customers. We offer a range of surface finishing options and can advise on material selection and part engineering concerns.

Advantages of Plastic Injection Molding

Injection molding is one of the most often-used manufacturing processes for creating plastic parts. Thanks to its high-precision, repeatability, and cost efficiency at scale, injection molding is used to make a variety of products and parts from the smallest medical insert up to large automotive & aerospace and defense parts.

GreensTone offers a wide array of plastic molding and finishing services, allowing us to act as a one-stop resource for low-cost plastic molding in China. We offer silk screening, pad printing, painting, and powder coating, and can provide testing and quality compliance checks on all components, including inspection with spectrophotometers.

Customers often rely on GreensTone’s expert engineering services, which provide design assistance as well as quality oversight. From molding structure, plastic material selection to detailed processes, the GreensTone team works to ensure our plastic molded parts provide reliable performance in the final application.

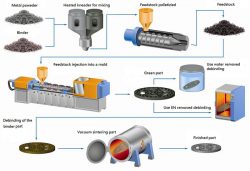

How Does Injection Molding Work?

The injection molding process requires an injection molding machine, raw plastic material, and a machined mold. The raw plastic material is first melted in the injection unit and is then injected into the mold — most often machined from steel or aluminum — where it cools and solidifies into the final plastic part. The key steps in the injection molding process are clamping, injection, cooling, and ejection.

Available Material for Injection Molding

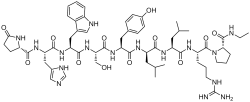

ABS: Acrylonitrile Butadiene Styrene (ABS) is an opaque thermoplastic and amorphous polymer and is an ideal choice for applications that require an inexpensive, strong, stiff plastic that holds up well to external impacts.

POM: POM is a plastic material featuring a very high tensile strength, with an outstanding resistance to creep, allowing it to bridge the gaps of material properties between most of the plastics and metals.

Nylon: Nylon plastic (PA) is a synthetic thermoplastic polymer commonly used in injection molding applications.

It’s a versatile, durable, flexible material often used to as a more affordable alternative other materials like silk, rubber, and latex.

PC: Polycarbonate (PC) is an amorphous thermoplastic. It is highly transparent, impact-/creep-resistant and can be applied within a wide range of temperature conditions.

PC/ABS: PC/ABS is a thermoplastic made of PC and ABS alloys, which combines the excellent properties of both materials. It is widely used in automotive trims, lampshades, handles and other components.

PVC: PVC plastic is budget-friendly, resistant to environmental degradation, chemicals, and alkalis, and has excellent tensile strength and hardness.

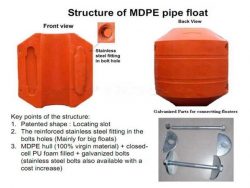

PE: Polyethylene is a thermoplastic polymer with a variable crystalline structure and a vast range of applications depending on the particular type. It is one of the most widely produced plastics in the world.

PP: Polypropylene(PS) injection molding material, is a thermoplastic addition polymer made by combining several propylene monomers.

PS: Polystyrene (PS) plastic is a naturally transparent thermoplastic that is available as both a typical solid plastic as well in the form of a rigid foam material.