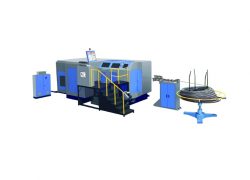

TWO STAGE PLASTIC RECYCLING MACHINE

Cut water cooling regeneration granulation machine is mainly suitable for the old and new high pressure polyethylene, low pressure polyethylene, polypropylene and other plastic regeneration granulation machine and engineering plastic color, processing plastic common plastic film, woven bags, convenient bag, basin, bucket, furniture, daily supplies, etc., is the plastic recycling industry most widely used, the most common, the most popular with users of plastic regeneration machinery.

FEATURES

FEATURES OF TWO STAGE PLASTIC RECYCLING MACHINE

Plastic is cut by the blade in the melt state, solidified after cooling by circulating water, different viscosity of high polymer can be used in this form of cutting grain, the melt state will not produce any dust, and the shape of the cutting grain is regular, packaging, transportation are more convenient;

According to the extrusion volume, automatically adjust the discharge amount and cutting speed of the die to change the size of the cut, or manually use different number of blades to change the size and shape of the cut;

The machine to grain cutting, cooling integration, save 4-6m long cold water tank, greatly reduce the area.

SPECIFICATION

SPECIFICATION OF TWO STAGE PLASTIC RECYCLING MACHINE

Brand

GUOLIAN

ModeL

SJ-A90

Product alias

Water pull strip granulator

Product use

Make waste plastic into plastic particles

Productive power

100

Number of rotation knife

6

Number of fixed knives

2

Cyclotron diameter

400

Feed mouth diameter

600

Filter screen plate aperture

80

Cut knife speed

120

The machine center is high

1600

Motor power (output)

30

Heating power

4

Applicable raw materials

PE,PP,Wire material, others

The number of screw

Single screw

The screw length

2070

Screw diameter

90

Outline dimension

4000x1500x1600

Weight

2600

Pot volume

100

After-sale service

Warranty for one year