SMALL PLASTIC RECYCLING MACHINE

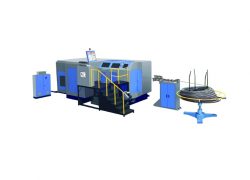

This machine consists of the following components: traction mechanism, extrusion mechanism, grain cutter structure, feeding-cooling mechanism.

How it works works:

1, and film machine linkage: film machine in the film process, the film material immediately sent to the granmachine traction mechanism, extrusion mechanism will edge half melt after extrusion to the mold, the cutter structure into uniform particles after feeding cooling mechanism inhalation and such as cooling pipe, eventually to the customer collection device, complete the waste recycling.

2, for the cutting machine: the cut edge material, orderly roll on the paper core, into the roll sent to granulation for granulation.

FEATURES

FEATURES OF SMALL PLASTIC RECYCLING MACHINE

This machine design has good reliability and stability, the host adopts famous brand frequency converter speed regulation, energy saving, conducive to environmental protection, simple structure, high degree of automation, at room temperature on the film material (bulk material) extrusion granulation, grain cutting, cooling. Will not change its chemical composition, especially for PE film, PVC film, PO film, waterproof material (polypropylene) and other materials granulation recycling, can solve the manufacturers of edge material accumulation, edge sheet online granulation and other problems, can produce good economic benefits.

SPECIFICATION OF SMALL PLASTIC RECYCLING MACHINE

Machine capcity

150L

300L

Production ability

60-80kg/h

100-150kg/h

Main motor power

18.5kw

30kw

Water adding device

125w

125kw

Heating power

1.5kw

1.5kw

Spindle speed

660r/min

660r/min

Machine Size

1500x700x1400mm

2000x800x1600mm