POWDER COATING

The atomized paint is sprayed on the metal surface and solidified after high-temperature baking to form the effects of anti-corrosion, anti scratch and beautifying the appearance. According to different requirements and use environment, the metal surface shall be polished, degreased, impurity removed, pickled and alkali washed before spraying and drying as required.

Is Powder-Coated Better Than Paint?

Powder coating spraying and oil spraying are generally surface treatment processes used in different environments and requirements. The advantages of powder spraying are high efficiency and large area operation. The disadvantage is that it is easy to cause uneven coating thickness on the surface of the workpiece, it is difficult to paint the dead corner position in place, and the environmental requirements are high. The advantages of fuel injection are short processing time and beautiful appearance. The disadvantages are high loss and difficulty to repair in the later stage.

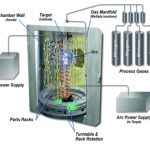

How Is Powder Coat Painting Done?

Powder coating process:

Workpiece preparation. Rough grinding of workpiece surface to remove burrs, edges and impurities.

The workpiece surface is flat. Fill the workpiece surface with the prepared putty. Allow to dry (24 hours).

Fine grinding. The workpiece shall be polished as a whole, including the putty part.

Cleaning. Clean the dust and impurities on the workpiece surface.

Dusting. Spray the prepared pigment agent.

Drying. The workpiece after powder spraying shall be placed in the oven as a whole to dry the surface powder layer.

After finishing the powder spraying process on the surface of the workpiece, it shall be packaged and shipped.