PVD COATING

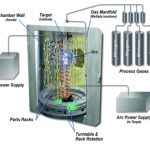

PVD coating, as we usually call it, refers to vacuum ion plating and vacuum sputter plating; Generally speaking, ncvm coating refers to vacuum evaporation coating. The basic principle is to vaporize the coating material under vacuum, and then deposit it evenly on the surface of the target part through electrons. The advantages of PVD are: good adhesion of coating (good mechanical properties), strong winding ability (adjustable target position and electroplating path), good coating quality (dense, uniform, high strength and long service life), simplified cleaning process (with cleaning function), and a wide range of plating materials (metal and non-metal can be plated).

Does PVD Coating Wear Off?

The wear resistance of PVD coating is different with different electroplating materials. For example, the CRN coating on the surface of bearings and cutting tools has strong wear resistance and is not easy to wear off.

Is PVD Better Than Stainless Steel?

PVD is a surface treatment process, which aims to improve or improve the performance and appearance of metal surfaces, and cannot be compared with the performance of raw materials.