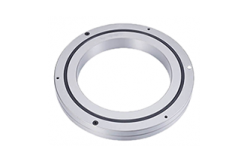

Samarium Cobalt Ring Magnets

Ring Shaped Samarium Cobalt (SmCo) Magnets

Samarium cobalt is the second strongest magnetic material after neodymium-iron-boron. Although its magnetism is not as strong as neodymium magnet, they are more corrosion-resistant and have a higher maximum working temperature.Ring shaped samarium cobalt (SmCo) magnet is one of the most popular industrial rare earth magnets. Smco ring magnets mainly work in high temperature environment or in applications with demagnetization. Ring shaped samarium cobalt ring magnets are commonly used in high temperature motors, aerospace, and military applications.

Types of Samarium Cobalt Ring Magnets

Samarium Cobalt(SmCo) Ring Magnet D12.7xd6.35×6.35mm

D12.7xd6.35×6.35mm

Samarium Cobalt(SmCo) Ring Magnet

Samarium Cobalt (SmCo) Ring Magnet D19xd9.5×6.35mm

D19xd9.5×6.35mm

Samarium Cobalt (SmCo) Ring Magnet

Samarium Cobalt (SmCo) Ring Magnet D25.4xd12.7×6.35mm

D25.4xd12.7×6.35mm

Samarium Cobalt (SmCo) Ring Magnet

Samarium Cobalt (SmCo) Ring Magnet D25.4xd15.8×6.35mm

D25.4xd15.8×6.35mm

Samarium Cobalt (SmCo) Ring Magnet

Samarium Cobalt (SmCo) Ring Magnet D25.4xd19x12.7mm

D25.4xd19x12.7mm

Samarium Cobalt (SmCo) Ring Magnet

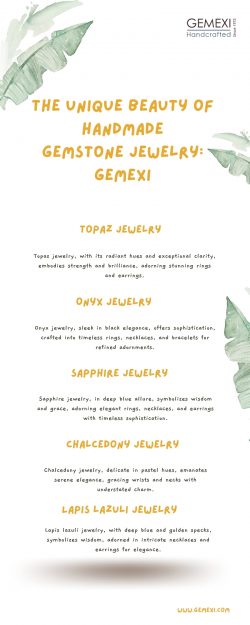

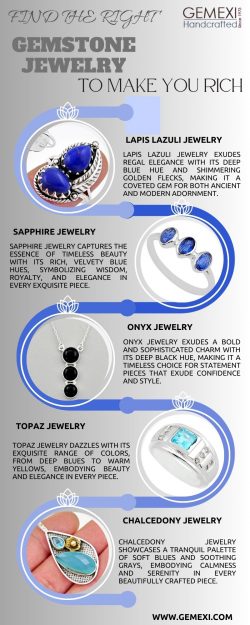

Available Grades of Samarium Cobalt Magnet Rings

There are many grades of annular samarium cobalt ring magnets to support a variety of industrial and commercial applications. The grade of samarium cobalt magnet rings typically range from 16 to 32 MGOe. Which allow for a balance of cost, magnetic properties and operating temperature resistance.

There are two main types of samarium cobalt(SmCo) magnet rings. The older type is usually expressed as (1-5), with one samarium atom in every five cobalt atoms; Newer samarium cobalt magnet rings are usually expressed as (2-17) and have an atomic ratio of two samarium atoms to 14-17 cobalt atoms( 14-17 atoms are actually composed of a mixture of transition metals, cobalt, copper and iron, of which cobalt content is the highest.

Corrosion Resistance Of SmCo Ring Magnets

Samarium cobalt (smco) rare earth ring magnet usually does not need any surface treatment for most applications, but coating or electroplating should be considered when working in acidic, high humidity, or vacuum environment.

Low environmental reactivity makes samarium cobalt ring magnets a good candidate for medical and aerospace applications. Before deciding on the design path, it is recommended to conduct an empirical evaluation of the magnet alloy in the operating environment. Generally, samarium cobalt magnets used in medical applications will be paliling coated and coated in materials suitable for the application.

Magnetization Options Of Samarium Cobalt Ring Magnets

Most commercial magnets are anisotropic, which means that they have an “easy” or preferred magnetization direction, and a directional field is applied during the compaction phase of the manufacturing process.

Samarium cobalt ring magnet can be magnetized axially or radially; Moreover, various pole configurations can be realized without affecting the direction of the magnetic material.

Handling of Samarium Cobalt Ring Magnets

Samarium cobalt ring magnet is very strong and fragile. In order to ensure safety and prevent damage, it needs reasonable handling and packaging.

Most receiving persons are not familiar with the strength of samarium cobalt magnets, which may lead to the fracture of samarium cobalt ring magnets. All personnel operating magnets should know how to handle the powerful ring magnets correctly. If the SmCo ring magnets collide with each other or with the solid surface, the brittleness of the alloy will lead to flying debris. If you are not careful, the larger SmCo ring magnet may cause personal injury.