Aluminium Extrusion

Aluminium Extrusion

ALUMINUM EXTRUSION SERVICE

LC Rapid aluminum extrusion service offers high quality, cost effective extrusion parts. With our professional and experienced engineering team and advanced machines, we not only make excellent tools but we also offer complex extruded parts as a manufacturer of aluminum extrusions. You can be rest assured because we exercise strict quality control through the whole manufacturing process guided by high quality standards of aluminium extrusion technology. Regular testing and verifying at various stages of manufacturing ensure us deliver an extraordinary quality product every time.

Aluminium Extrusion Technology

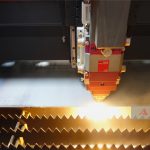

Aluminum extrusion is the process of forming the aluminum into the desired shape and geometry. Firstly, the mold is fabricated according to the drawing. And then extrude different types of custom aluminum extrusion profiles from the mold by heating and forcing the aluminum billet through the die.

Aluminum extrusions are known for their great strength, lightweight, and good conductivity, which make them an outstanding choice for diverse end-use applications (e.g. enclosures and heat sinks). It is the most cost-effective for high-volume production runs of metal parts due to the significantly low unit price.

Advantages of Custom Aluminium Extrusion

l Part ProductionPart Production

Piece price is significantly lower with standard aluminium extrusion services versus other metal forming process.

l StrengthStrength

Fabricated aluminium extrusions are very strong, making them suitable for cold weather applications that require high strength. Aluminum extrusions also have high rust and corrosion resistance.

l Finishes SelectionFinishes Selection

Aluminum extrusions can be anodized, powder coated, polished, and etc.

l PrecisionPrecision

We can conform to very tight tolerances base on customers requirements.

Aluminum Extrusion Process

After we receive your order, we will:

Step 1: Supply a complete cross-sectional drawing for you after review and discuss about your CAD files.

Step 2: Fabricate dies and extrude a sample to get your approval.

Step 3: Make the modification on the die if needed.

Step 4: Exercise process control when extruding your parts.

Step 5: Select from a variety of finishes processing to achieve the effect you want.

Step 6: Inspect finished extruded parts to avoid any dimension deviation.

Aluminum Extrusion Tolerance

The tolerance depends on shape and structure. If you need a very precise tolerance, we can follow it once we confirm your designs.

Aluminum Extrusion Material

Alloy: 6060, 6063, 6061, 6082, 2A12, 2024, 5052, 7075 and etc. (Others Available)

Aluminum Extrusion Finishes

l Electrophoresis

After applying electrophoresis, you can get a glossy surface with excellent impact resistance. The electrophoresis layer improves the resistance to chipping, scratching, and fading.

l Powder Coating

Typically, powder coating is commonly used on the market to color the aluminum extrusions. It is also applied to cover extrusion lines and defects.

l Anodizing

Anodizing is done to improve the corrosion and wear resistance, enhancing the parts durability. Sometimes anodizing is done simply get colors on surfaces, like black, red, blue, gold, and etc.

Aluminum Extrusion Solutions

l Solar Energy

Aluminum extrusion is transforming the solar energy industry with its extraordinary physical properties such as strength, malleability, lightweight, and high corrosion resistance. Aluminum is considered to be the preferred state-of-the-art frames and structures for the solar panels, supports and connectors.

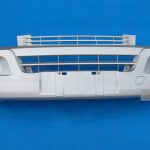

l Automotive

Aluminum is approximately one-third the weight of steel, but with the similar strength with steel. Aluminum extrusion is helping car makers to reduce vehicle weight precision, create innovative parts. Its quality and mass production technologies have been proven by their actual applications such as bumper beam, motor mount, frame members and other automobile parts.

l Electronics

The custom aluminum extrusion has standout durability, high corrosion resistance, weatherproof long-lasting property, which is why there are so many electronics applications made by extrusion, including housings, heat sinks, connectors.

Common Applications of Aluminum Extrusion Technology

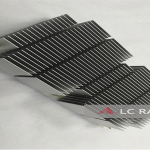

l Heat Sink

The extruded heat sink is the most commonly used type of heat sinks in the market. The extrusion process makes it cost effectiveness, high quality and excellent thermal conductivity.

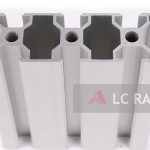

l Aluminium Profile

Aluminum profile is used in a wide range of applications due to it’s strong tensile strength, flexibility, and durability.

l Cylinder Tube

Aluminum cylinder tubes are playing a significant role in various industry sectors.