Application Field and Market Prospect of Cold Formed Steel

1. Application field of cold roll forming machine

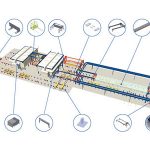

The continuous cold-formed steel forming unit mainly includes uncoiling, straightening, shearing and butt welding, material storage, forming (welding, shaping), cutting to length, inspection and collection and some special processes. Its equipment is basically similar to the high-frequency welded pipe unit, but the cold roll forming machine has various forms. According to the product specifications, it can be divided into three major types as general cold-formed steel forming unit, open cold-formed steel forming unit and wide wave steel panel forming unit. These three types have different structure and product focus.

The general cold-formed steel forming unit can produce not only non-welded cold-formed copper products with simple cross-section, but also welded closed profiles, such as round tubes, square rectangular tubes and other special-shaped tubes.

The product is widely used in light steel structure, automobile manufacturing, highway transportation, logistics equipment, electrical cabinet, etc. Typical products are: “C”, “Z” sandalwood strips; Z-shaped steel with bevel edge curling; Z-shaped steel with unequal edge curling; Z-shaped steel with unequal edge curling; color steel profiled plate; U-shaped channel steel for automobile girder; upper and lower edge steel; marine fender, small warehouse board; Japanese and European highway guardrail; guide rail for suspension conveyor, etc.

2. Market prospect of cold roll forming machine

The production of cold-formed section steel in China started in the 1950s and 1960s, mainly serving the agricultural machinery industry. By the 1980s, it was the first big development climax. It began to serve in the automobile, bus, building doors and windows, transportation, shelves, electrical appliances and other industries. So far, more than 1000 sets of units have been produced, and 42 sets of larger units with diameter of more than 200 mm are under construction. The maximum pipe diameter is 660mm.

The production capacity of cold-formed steel in China has reached 15 million tons/year, basically meeting the market demand of 4.38 million tons/year. The export volume is very small, only a few thousand tons, and the cold bending output accounts for 2.4% of the steel output. There are more than 2000 kinds of products. The steel grades have developed from single plain carbon steel to high strength, weather resistance, fire resistance and other steel grades. Cold formed steel has become an indispensable rising star in steel products, and is favored by the majority of users.