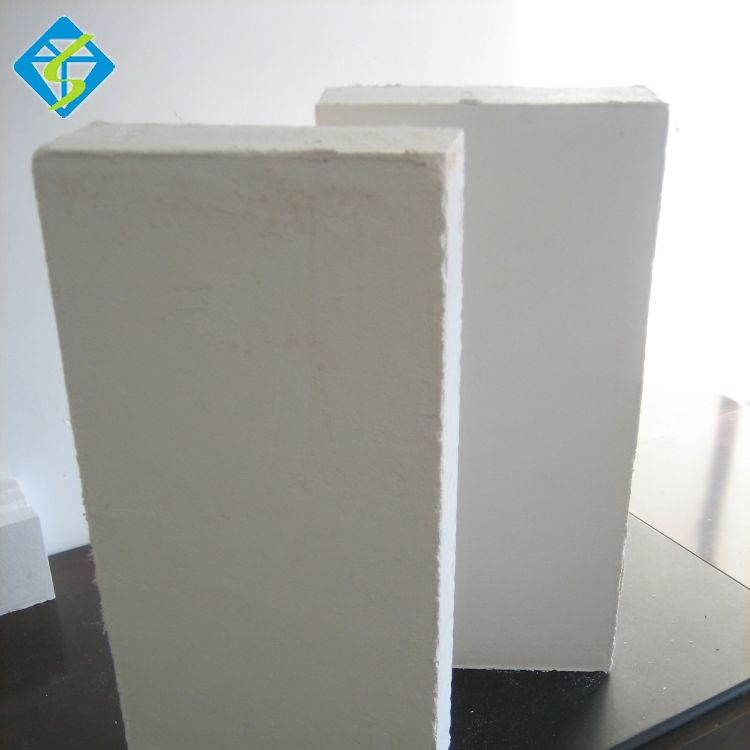

Calcium Silicate Insulation Board At 650℃

A calcium silicate insulation board is a non-asbestos insulation product that can withstand continuous working temperatures from 650℃ to 1100℃. It is lightweight, has low thermal conductivity, high strength, is easy to install, reliable and durable. Available in 2 grades, 650 and 1000 and 1100, they are commonly used as a backup insulation for furnaces in the steel, petrochemical, ceramic, cement and glass industries or for fire protection in building construction. It not only saves energy but also increases productivity and provides protection for personnel in industrial safety. In housing construction, calcium silicate insulation board is also used as a fireproof insulation material for ceilings and walls and as a decorative sound-absorbing material.

Properties of calcium silicate insulation board

Thermal shock resistance and stability

Consistently low thermal conductivity

High structural strength at high temperatures

Non-combustible

Electrical insulation properties when dry

Easy to process

Insoluble in water, non-corrosive

Applications

The calcium silicate insulation board is easy to install and handle, and its low thermal conductivity makes it ideal for insulation. It is non-toxic and asbestos-free.

The calcium silicate insulation board is widely used in urban heat networks, metallurgy, electronics, machinery, steel, petrochemicals, ferrous and non-ferrous metal casting, aluminum, ceramics, glass and other industries.

Advantages of calcium silicate insulation board.

Asbestos-free

No fibers

No known health hazards

Low thermal conductivity

Lightweight

Easy to work with and handle

Better than BS3958 Part II 1982 (insulation)