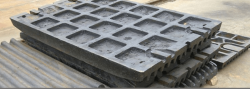

Refractory Bricks

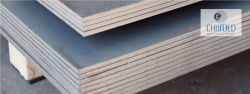

Refractory bricks are a special type of construction material used in high-temperature environments such as furnaces, kilns and fireplaces. These bricks are made of refractory ceramic and can withstand temperatures up to 1,800 degrees Fahrenheit (982 degrees Celsius) without damaging or losing their structural integrity.

There are several types of refractory bricks to choose from, each with its own unique properties and applications. Some common types include fireclay refractory bricks, alumina refractory bricks, magnesia-based bricks, etc.

Refractory clay bricks are made from a mixture of refractory clay and other materials, such as alumina and silica. They are known for their high resistance to thermal shock and are commonly used in applications such as furnace linings and fireplaces.

High alumina bricks are made from a mixture of alumina and other materials (e.g. silica). They are highly resistant to fire and are often used in furnace linings, kiln linings and other high-temperature equipment.

Refractory bricks are also classified into different grades according to their resistance to acid, alkali and neutral. Acid-resistant bricks are used in acidic slag environments, alkaline bricks are used in alkaline slag environments, and neutral bricks are used in neutral slag environments.

Another important characteristic of refractory bricks is their apparent porosity. The porosity of a refractory brick can be measured as a percentage, which is an indicator of the number of open pores in the brick structure. Porosity affects the thermal conductivity, mechanical strength and chemical resistance of the brick.

Refractory bricks also come in different shapes and sizes, depending on their intended application. Standard bricks are rectangular in shape, while profiled bricks can be customized to meet specific needs.

When selecting a refractory brick for a specific application, it is important to consider factors such as the ambient temperature, the type of fuel to be used and the chemical properties of the material to be used. In addition, it is important to ensure that the blocks used are compatible with the equipment they will be installed in.

Refractory bricks are an important part of a wide range of industrial and commercial applications, including furnace linings, kiln linings and fireplaces. They are made of refractory ceramic and can withstand temperatures up to 1,800 degrees Fahrenheit (982 degrees Celsius) without damaging or losing their structural integrity. They come in different types, categories, shapes and sizes, and it is important to select the correct type of brick for the intended application and ensure they are installed correctly.