Chemical Processing Machines For The Chemical Sector

Chemical Process Equipment For The Chemical Sector

Benefits of SUNKAIER Chemical Processing Machines in Chemical Industry

SUNKAIER developed supporting design software, such as CFD simulation software, which can build a three-dimensional visual equipment model based on the process equipment design scheme, visually present the design effect of the scheme, and facilitate designers to grasp the design dynamics and sort out the design ideas.

SUNKAIER has strengthened the research and development of the anti-corrosion performance of equipment and taken various effective treatment measures based on it. High purity ferritic stainless steel, titanium alloy and other materials with good corrosion resistance are used as raw materials for equipment manufacturing.

SUNKAIER owns professional mechanical seal Department, with many patents such as invention patents of magnetic seals and utility model patents of mechanical seals. And has made a number of technical achievements in the fields of fluid dynamic seal of process equipment and parallel mechanical seal structure.

Application of Advanced Process Equipment Technology in Chemical Industry

With the continuous improvement of science and technology and the upgrading of manufacturing processes, new requirements are put forward for the use function, performance and quality of process equipment. SUNKAIER actively draws on mature and advanced design concepts and experience at domestic and abroad, continuously optimizes and improves the current process equipment structure design system, and simplifies the structure as much as possible on the basis of design standards, reducing the use of raw materials and equipment manufacturing costs, so that SUNKAIER ‘s process equipment has both structural novelty and economic applicability.

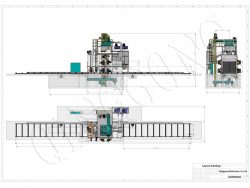

Actually, the working conditions of process equipment are complex, and they will be continuously affected by corrosion. Therefore, SUNKAIER has strengthened the research and development of the anti-corrosion performance of equipment and taken various effective treatment measures based on it. High purity ferritic stainless steel, titanium alloy and other materials with good corrosion resistance are used as raw materials for equipment manufacturing. Meanwhile, the brush corrosion-resistant coating on the surface of equipment, deeply develop surface corrosion prevention technology, and take chemical heat treatment or electrochemical protection measures which are adopted.

The production site environment of chemical enterprises is complex, and some equipment will continue to be affected by high pressure, strong corrosion and other factors in the working state. For example, the sealing performance of equipment is insufficient, which not only can not give full play to the use performance of equipment, but also has potential safety hazards. SUNKAIER owns professional mechanical seal Department, with many patents such as invention patents of magnetic seals and utility model patents of mechanical seals. And has made a number of technical achievements in the fields of fluid dynamic seal of process equipment and parallel mechanical seal structure.

Common applications in chemical industry:

Basic Chemical Products

Fine Chemical Product

Special Purpose Chemical

Polymer

Active Pharmaceutical Ingredient

Fertilizer

In addition, in the special chemical industry, especially in the treatment of such challenging and critical processes as mixing, kneading, crushing, stirring, vulcanization, and repolymerization of high viscosity and high elastoplastic materials, SUNKAIER continuous or batch kneader reactors have excellent characteristics such as uniform stirring, no dead angle, self-cleaning, and high kneading efficiency, which has played a vital role in promoting the efficient and effective production of the chemical industry

Kneader Reactor has a wide range of functions, varieties and applications. Especially suitable for chewing gum, feed, bubble gum, toothpaste, plastic, rubber, silicone rubber, dyes, pigments, printing ink, food gum base, pharmaceutical agents, architectural coatings, carbon, fine grain, high viscosity sealant, neuter glass glue, aluminum silver paste, silica gel, pulp, cellulose, battery slurry, dye, organic silicon resin, cosmetics and other industries.