RAPID PROTOTYPING SERVICE

LC Rapid is an expert in producing super quality and cost-effective prototypes among many Chinese prototype manufacturers. We are able to analyze engineering drawings professionally and resolve different problems that occur through the whole production process calmly. Our one-stop-shop for various rapid manufacturing services and a wide range of secondary operations guarantee the best quality of the product and a high level of customer service.

Introduction of Rapid Prototyping Service

Rapid prototyping production involves specialized manufacturing processes to produce high quality, low cost, quick-turn functional metal or plastic prototypes of 3D computer-aided design (CAD) data. Before moving into production, prototypes allow you to test the part functionality, form, fit of your product design and prototyping. Rapid prototyping system enables customers to cut production time and cost dramatically since there is no mould to create. There is no better way to verify a design or to evoke clients interest than to take advantage of high-performance rapid prototyping services.

Advantages of Rapid Prototyping Manufacturing

Deliver accurate and excellent cosmetic items quickly.

Correct errors and perfect product design.

Produce multiple design versions quickly with a different colors, textures, and expansive service finishing processes.

Present physical concept model to your customers and stakeholders at an early stage of the product development process.

Save time and cost by minimize risk of design flaws.

Evaluate new designs’ appearance, dimensions and features.

Test the market early and frequently with prototypes before moving into production

Different Types of Rapid Prototyping Processes

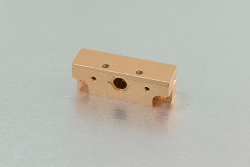

CNC Machining

Rapid prototyping CNC machining service is ideal for making custom, quick-turn prototypes and low-volume parts from plastic or metal.

Plastics: ABS, PC, POM, PP, PMMA, PBT, Nylon, Nylon+30%GF, PEEK, PVC, PTFE (Teflon), and ULTEM.

Metal: Various grades of aluminum, steel, stainless steel, brass, copper, bronze, zinc, magnesium, titanium.

CNC machining is a manufacturing process with a high degree of automation, allowing you to get parts with high precision and extraordinary surface look. CNC machining can also achieve all the features needed for functional prototyping, allowing you to test part functionality without producing expensive tooling.

LC Rapid CNC prototyping china has advanced, multi-axis CNC machining centers which can produce highly dimensional accuracy, surface smooth CNC prototypes quickly. There is a wide range of surface finishing operations you can select from, such as sandblasting, anodizing, plating, painting, printing, lasering, polishing, powder coating, knurling, and etc.

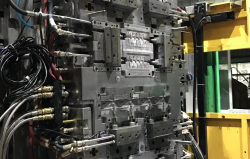

Vacuum Casting

Vacuum Casting is a mid-to-low production volume manufacturing process in which a liquid polyurethane material is filled into a silicone mold, and then the plastic part can be produced in a vacuum chamber. We produce parts with showroom quality out of polyurethane material which is plastic-like and rubber-like material. These materials have the properties close to real injection moulding plastics, such as ABS, PP, POM, PC, PMMA (Acrylic), Rubber, etc. We can also offer a wide range of finishing services to exceed your desired look. Typically, a silicone mold can cast about 15-25 parts in a fast turn-around and with cost-effectiveness, which make vacuum casting a better choice over other plastic manufacturing process like injection molding.

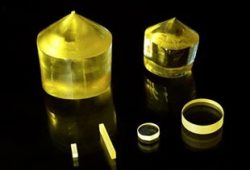

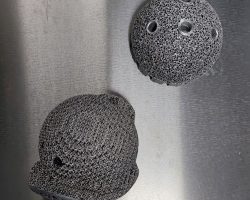

3D Printing

3D printing is the additive manufacturing process that builds a physical object layer by layer. LC Rapid’s latest 3D printing technologies can ensure high quality printed prototypes quickly from a wide range of 3D printing materials- Printed prototypes can be completed in as little as 1 day. 3D printing is a perfect choice to produce one prototype or low production volume runs, and can be used to create parts with complex structure and intricate geometry.

Featured Rapid Prototyping Resources

Rapid Prototyping FAQ

What is unique about the LC Rapid’s rapid prototyping services?

Our rapid prototyping services include CNC machining, vacuum casting, 3D printing, plastic injection molding. LC Rapid high precision products offer a wide variety of extensive options to allow our team to exceed client’s expectations for design flexibility, material, precision, functionality, and surface finishes.

What type of secondary surface finishes does LC Rapid provide?

To help our customers to find the right look and feel for their great products, we offer a wide variety of secondary surface finishing services. Some of our most preferred surface finishing capabilities include anodizing, painting, plating, powder coating, sanding, brushing, vapor polishing, polishing and blasting.

What are LC Rapid’s quality management system and processes to enhance customer satisfaction for rapid prototyping services?

We continue to improve our quality management system and processes starting from sales personnel and manufacturing engineers, and then along with quality control team work, until packing and shipment to ensure excellent finished prototypes for our customers. We are also glad to take detailed pictures and video files showing all production steps for clients who can’t visit our facilities in person.

Do you offer design services, secondary processes, or product development support as an extension of rapid prototyping services?

For clients who don’t have 3D file or their current 3D CAD model is not ready for manufacturing, we can offer great quality CAD model with clients’ idea. Secondary processes and additional design for manufacturing support are available for rapid prototyping services. We can also offer light assembly services and reverse engineering service using the legacy parts.