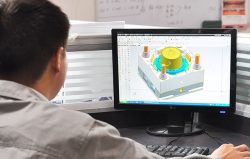

Development of Powder Injection Molding Technology

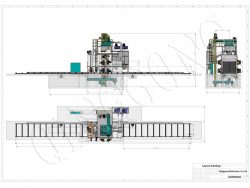

Powder injection molding is a new molding technology of parts, which combines traditional powder metallurgy technology with modern plastic injection molding technology. The biggest feature of this technology is that it can directly manufacture the parts with final shape, reduce the machining amount and save raw materials to the maximum extent, and solve the problem of difficult forming of complex shape products in the field of powder metallurgy; Moreover, the material adaptability of this technology is wide. All metals, alloys and ceramics that can be made into powder can be manufactured into parts by this technology. In addition, this technology can also achieve full automatic continuous production, excellent material properties and high dimensional accuracy of products.

1. Powder Injection Molding Technology

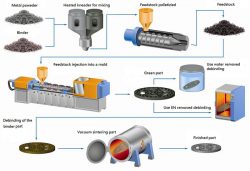

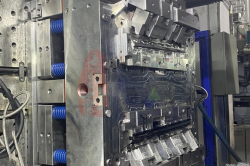

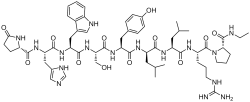

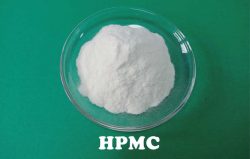

Firstly, the solid powder is mixed with certain additives evenly, and after granulation, in the heating state, the granular material is injected into the mold cavity by a metal injection molding machine for condensation forming. Then the binder in the forming blank is removed by chemical or thermal decomposition method, and finally, the final product is obtained by sintering densification.

2. Development Scale of Powder Micro Injection Molding

In recent years, the development of micro system technology in various fields is very rapid, and it also puts forward higher requirements for the manufacture of three-dimensional micro complex components used in micro engineering. It is hoped that the micro devices can meet the performance requirements and realize large-scale production at the same time. The main components of the micro system include micro mold, micro mechanical structure for sensors and accelerators, biosensors, micro fluid components, micro reactors and so on.

The shape of these components is complex and the volume is small. Using the existing micro machining technologies such as micro cutting, laser cutting, silicon etching technology, etc., the production efficiency is low, and it is unable to carry out large-scale production. In recent years, the metal injection molding process developed on the basis of powder injection molding provides the most potential preparation technology for realizing the large-scale production of micro components.

3. Achievements of Powder Injection Molding at Home and Abroad

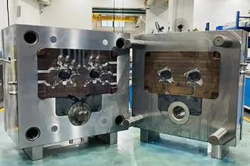

At present, Germany, Japan, Singapore, the United States and the United Kingdom are the main countries to carry out the research. Among them, Germany took the lead in developing and achieved outstanding results. In China, Beijing University of science and technology, Central South University and Dalian University of technology have also carried out a series of research work in this field. The research work includes: developing moulds of metal injection molding with independent intellectual property rights, which are suitable for traditional injection molding machine.

Using carbonyl iron powder and iron nickel alloy powder as raw materials, the micro gear with the tip circle diameter less than 1 mm was successfully realized on the traditional injection molding machine.