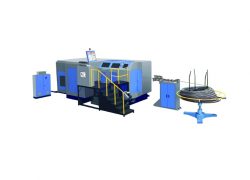

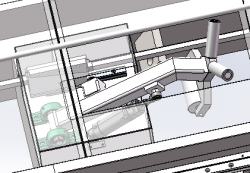

PP BLOWN FILM MACHINE

The film blowing unit is suitable for the production of polypropylene (PP) plastic film, widely used in food, clothing, textiles, daily necessities and other civilian products and industrial supplies packaging.

FEATURES

FEATURES OF PP BLOWN FILM MACHINE

The die head can choose 360 degrees of rotation, can enhance the strength and uniformity of the plastic film.

The screw and material cylinder are made of 38CRMOALA alloy steel, through nitriding treatment and precision processing, high hardness, strong corrosion resistance, durable.

Die head coated with hard chromium, its structure is spiral mandrel type, uniform molten material and good film finish; air cooling device is labyrinth structure with uniform air volume. The circulating water is used to achieve good transparency.

The winding device adopts pressure friction or central winding, adjusted by torque motor, smooth winding and easy roll changing.

SPECIFICATION

SPECIFICATION OF PP BLOWN FILM MACHINE

MODEL

SJ50

SJ.60

SJ.65

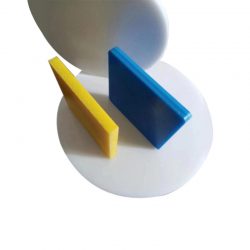

Suitable material

PP

Max film blowing width

100-500

150-600

200-800

Film thickness (mm)

0.03-0.11

0.03-0.11

0.03-0.11

Max output

30

45

60

Screw diameter

Φ45

Φ55

Φ65

Screw L/D ratio

30:1

Barrel cooling

370w x 2

370w x 2

370w x 3

Main motor power (kw)

11

15

18.5

Die mouth

Φ150

Φ250

Φ300

Cooling fan

1.5

1.5

2.2

Traction roll width (mm)

Φ165 x 550

Φ165 x 650

Φ165 x 850

Traction motor power (kw)

5-60

Traction speed

0.75

Rewinding speed

5-60

Rewinding power (N.M)

5

5

6

Dimension L x W x H

3.5 x 2 x 3.5

4.2 x 2.5 x 4

4.6 x 2.8 x 4.5