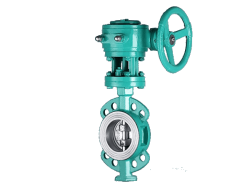

Fluorine Lined Butterfly Valve

In the well-known butterfly valve technology, fluorine lined butterfly valve sealing form mostly adopts a sealing structure, and the sealing material is rubber, polytetrafluoroethylene, etc. Due to the limitation of butterfly valve structural characteristics of the fluorine lined butterfly valve, it is not suitable for industries such as high-temperature resistance, high-pressure resistance, corrosion resistance, and wear resistance. Contact our butterfly valve china manufacturer for more information now!

Fluorine Lined Butterfly Valve vs. Triple Eccentric Butterfly Valve

An existing more advanced butterfly valve is a triple eccentric metal hard-sealed butterfly valve, the fluorine lined butterfly valve body, and the valve seat are connected components, and the sealing surface layer of the valve seat is welded with temperature-resistant and corrosion-resistant alloy materials. The multi-layer soft laminated sealing ring is fixed on the fluorine lined butterfly valve plate. Compared with the traditional butterfly valve, fluorine lined butterfly valve has high-temperature resistance, is easy to operate, and has no friction when opening and closing. When closing, the torque of the transmission mechanism increases to compensate for the sealing, which improves the butterfly valve. The advantages of sealing performance and extended service life. This type of valve should generally be installed horizontally in the pipeline.

Fluorine Lined Butterfly Valve Datas

Fluorine Lined Butterfly Valve Technical Parameter

Material of Fluorine Lined Butterfly Valve Main Parts

Wafer type

dn

l

d

d 1

d 2

f

z-φd

h 2

h 1

d

d1

z-φd

kg

40

33

145

110

85

3

4-φ18

270

80

145

110

4-φ18

4

50

43

160

125

100

3

4-φ18

280

85

160

125

4-φ18

5

65

46

180

145

120

3

4-φ18

290

93

180

145

4-φ18

7

80

46

195

160

140

3

4-φ18

310

100

195

160

8-φ18

9

100

52

215

180

155

3

8-φ18

340

110

215

180

8-φ18

13

125

56

245

210

185

3

8-φ18

355

120

245

210

8-φ18

15

150

56

280

240

210

3.5

8-φ23

380

160

280

240

8-φ23

24

200

60

335

295

265

3.5

8-φ23

430

245

335

295

12-φ23

38

250

68

390

350

320

4

12-φ23

450

260

405

355

12-φ26

60

300

78

440

400

370

4

12-φ23

480

300

460

410

12-φ26

70

350

78

500

460

420

4

16-φ23

600

320

520

470

16-φ26

80

400

102

565

515

475

4.5

16-φ25

630

330

580

525

16-φ30

120

450

114

615

565

525

4.5

20-φ25

655

380

640

585

20-φ30

165

500

127

670

620

580

5

20-φ25

680

390

715

650

20-φ33

205

600

154

780

725

690

5

20-φ30

730

450

840

770

20-φ36

250

700

165

895

840

800

5

24-φ30

790

480

910

840

24-φ36

320

800

190

1010

950

905

5

24-φ34

880

580

1020

950

24-φ39

395

900

203

1110

1050

1005

5

28-φ34

930

625

1120

1050

28-φ39

450

1000

216

1220

1160

1115

6

28-φ34

1000

660

1255

1170

28-φ42

600

1200

254

1450

1380

1325

6

32-φ41

1300

780

1485

1390

32-φ48

825

Flange type

dn(mm)

nps(inch)

l

d

d1

d2

f

b

z-φd

w

do

h

wt(kg)

pn1.0mpa

40

11/2

106

145

110

85

3

18

4-φ18

160

140

10

50

2

108

160

125

100

3

20

4-φ18

200

160

12

65

11/2

112

180

145

120

3

20

4-φ18

250

165

14

80

3

114

195

160

135

3

22

4-φ18

250

170

16

100

4

127

215

180

155

3

22

8-φ18

300

180

18

125

5

140

245

210

185

3

24

8-φ18

300

275

20

150

6

140

280

240

210

3

24

8-φ23

200

295

38

200

8

152

335

295

265

3

26

8-φ23

200

320

74

250

10

250

390

350

320

3

28

12-φ23

240

385

105

300

12

270

440

400

368

3

28

12-φ23

240

390

142

350

14

290

500

460

428

4

30

16-φ23

240

460

179

400

16

310

565

515

482

4

32

16-φ25

280

510

220

450

18

330

615

565

532

4

32

20-φ25

280

540

268

500

20

350

380

620

585

4

34

20-φ25

320

570

378

600

24

390

780

725

685

4

36

20-φ30

320

660

608

700

28

430

895

840

800

5

40

24-φ30

360

710

1050

800

32

470

1010

950

905

5

44

24-φ34

360

780

1320

900

36

510

1110

1050

1005

5

46

28-φ34

380

885

1795

1000

40

550

1220

1160

1115

5

50

28-φ34

400

990

1900

pn1.6mpa

40

11/2

106

145

110

85

3

18

4-φ18

200

140

10

50

2

108

160

125

100

3

20

4-φ48

200

160

12

65

11/2

112

180

145

120

3

20

4-φ18

250

165

13

80

3

114

195

160

135

3

22

8-φ18

250

170

14

100

4

127

215

180

155

3

24

8-φ18

300

180

16

125

5

140

245

210

185

3

26

8-φ18

300

275

18

150

6

140

280

240

210

3

28

8-φ23

200

295

42

200

8

152

335

295

265

3

30

12-φ23

200

320

78

250

10

250

405

355

320

3

32

12-φ25

240

385

120

300

12

270

460

410

375

4

34

12-φ25

240

390

145

350

14

290

520

470

435

4

38

16-φ25

240

460

202

400

16

310

580

525

485

4

40

16-φ30

280

510

235

450

18

330

640

585

545

4

44

20-φ30

280

540

368

500

20

350

705

650

608

4

46

20-φ34

320

570

420

600

24

390

840

770

718

5

54

24-φ41

320

660

750

700

28

430

910

840

788

5

54

24-φ41

360

710

1028

800

32

470

1020

950

898

5

54

24-φ41

380

780

1690

900

36

510

1120

1050

998

5

54

28-φ41

400

885

1815

1000

40

550

1255

1170

1110

5

60

28-φ48

500

990

2050

pn2.5mpa

40

11/2

106

145

85

3

18

4-φ18

200

140

11

50

2

108

160

100

3

20

4-φ18

200

160

13

65

11/2

112

180

120

3

22

8-φ18

250

165

14

,,

80

3

114

195

135

3

22

8-φ18

250

170

16

100

4

127

230

160

3

24

8-φ23

300

180

18

125

5

140

270

188

3

28

8-φ25

300

275

20

150

6

140

300

218

3

30

8-φ25

240

295

48

200

8

152

360

278

3

34

12-φ25

240

320

88

250

10

250

425

332

3

36

12-φ30

280

385

145

300

12

270

485

390

4

40

16-φ30

280

390

157

350

14

290

550

448

4

44

16-φ34

320

460

222

400

16

310

610

505

4

48

16-φ34

320

510

353

450

18

330

660

555

4

50

20-φ34

360

540

405

500

20

350

730

610

4

52

20-φ41

360

570

448

600

24

390

840

718

5

56

20-φ41

380

660

DN

DN15-DN1000

PN

PN10-PN25

Body

cast Iron

carbon steel

stainless steel

Lined

PTFE, FEP, PCTFE, PVDF, UHMW-PE etc

Connection

Wafer

Flanged

Lug

Operation

Lever

Gear

Pneumatic