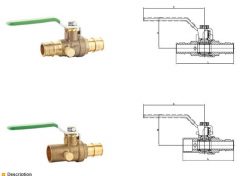

Full Welded Ball Valve

Since the full welded ball valve seat is composed of a carbonized Teflon seal ring and a disc spring, it has strong adaptability to pressure and temperature changes, and will not cause any slippage within the marked pressure and temperature range. The processing of the sphere is tracked and detected by an advanced computer detector, so the processing accuracy of the sphere is high.

Due to the high quality ball valve body material is the same as the pipe material, there will be no uneven stress, and no deformation due to earthquakes and vehicles passing the ground, and the pipe is resistant to aging. The metal ball valve body of the sealing ring is made of RPTFE with a content of 25% Carbon, which guarantees no leakage (0%).

The direct-buried fully welded ball valves can be directly buried in the ground, instead of building high and large valve wells, only small shallow wells are set on the ground, which greatly saves construction costs and engineering time.

Full Welded Ball Valve Technical Specification

Size: 1/2″~16″(DN15~DN400)

Pressure: Class ANSI #150~900, PN10~PN150

Fully welded ball valves body material: Carbon steel, Stainless steel, Alloy steel, or others

Standard compliance: EN12516, DIN3357-1 or equivalents

End connections: Flanged Ends OR BW, SW

Direct mounting with pneumatic or electric actuators

Full port or regular bore; double block and bleed

Full Welded Ball Valve Structure Features

The high quality ball valve is composed of a full welding body together with the RPTFE sealing which ensures the full welded ball valve can work well in there are countries or chemical substances.

The floating ball structure and the flexible seat will ensure the ball and the sealing connects each other tightly. Even when the pressure is not stable, the fully welded ball valves can also have good sealing.

The stem can be extended which is good for keeping the temperatures table.

Full Welded Ball Valve Datas

Main Connection Dimensions of Full Welded Ball Valve

Materials of Fully Welded Ball Valve Main Parts

Main Performance Specification of Full Welded Ball Valve

DN

PN

L

D

D1

D2

H

B

H1

Weight (KG)

(N.M)

15

40

210

15

21.7

42.7

103

129

22

–

3-4

20

40

230

20

27.2

48

118

159

23

–

5-7

25

40

260

25

34.0

60

121

159

34

–

8-11

32

40

260

32

42.7

76

120

230

34

–

12-18

40

40

300

40

48.6

89

127

230

43

–

25-32

50

40

300

50

60.5

114

170

300

44

–

38-45

65

25

300

65

76.3

140

185

300

71

–

55-65

80

25

300

80

89.1

165

210

400

77

–

110-120

100

25

325

103

114.3

216

253

400

102

–

200-250

125

25

350

125

1393

219

273

450

102

–

300-340

150

25

490

150

1652

355

300

450

107

–

450-480

200

25

580

200

216.3

356

345

252

123

–

750-800

250

25

550

250

267.4

457

572

236

122

–

900-950

300

25

630

300

318.5

5C8

697

331

155

–

1200-1300

350

25

762

337

355.6

559

764

331

187

–

1900-2000

400

25

840

387

406.4

660

810

360

221

–

–

500

25

1010

489

508.0

812

973

413

221

–

–

*The dimension of welded end connection can be designed and manufactured according to the buyers’ request.

Part Name

Materials

Handle

Carbon steel

Retaining ring

SS304

O- ring

Viton

Spindle

SS420

Gasket

RPTFE

Ball

SS304

Ball seat

RPTFE

Back-up ring

SS304

Spring washer

SS304

Valve casing

St.37.0