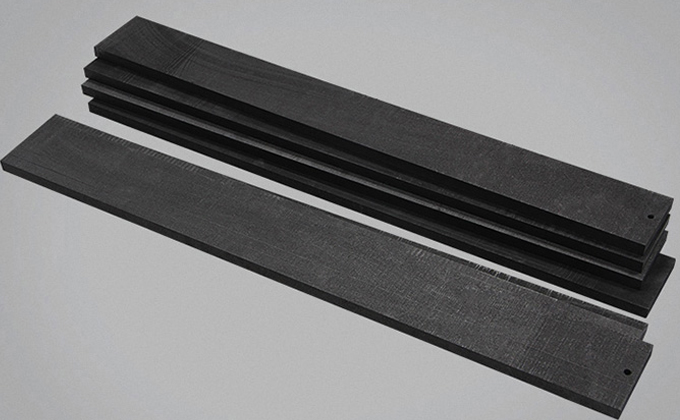

Graphite Anode Plate

Graphite anode plate has the advantages of high-temperature resistance, good conductivity, easy machining, good chemical stability, acid and alkali corrosion resistance, and low ash content. It can be used for an electrolyzing aqueous solution to produce chlorine and caustic sodium, and electrolyzing salt solution to produce alkali; Graphite anode plate can also be used for electroplating various metals and non-metallic carriers. For example, a graphite anode plate can be used as a conductive anode for an electrolytic salt solution to produce caustic soda. It can also be used for sewage treatment in chemical, electronic, and textile industries.

What factors will affect the service life of graphite anode plate

The development of the graphite anode plate industry has entered a new stage. The main raw material of graphite anode plate is crystalline natural graphite, so it maintains the original physical and chemical properties of natural graphite.

Performance

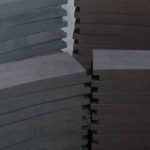

The oxidation resistance and high-temperature resistance of graphite sheets plates also directly determine their service life.

Density

The higher the density, the longer the service life of the carbon graphite plate. For example, if the density is 1.7, it will more than double the service life of 1.5.

Specifications

The general thickness is between 2-3cm, but if the graphite anode plate is too thin, the control of material layout can determine its durability.

Application of Graphite Anode Plate

In the electrolytic industry, graphite anode plate has been used as anode for more than 100 years. Graphite anode plate has the advantages of high-temperature resistance, good conductivity, easy machining, good chemical stability, acid, and alkali corrosion resistance, and low ash content. It is used in many fields:

an electrolyzing aqueous solution to produce chlorine and sodium, and electrolyzing salt solution to produce alkali;

a conductive anode for producing caustic soda by electrolysis of salt solution;

a conductive anode in the electroplating industry.