PCB Functional Test & Programming

If you want to ensure the good quality for delivery of every board, the PCB programming, and PCB functional test is the best way to test.

PCBA Online Programming:

Before finishing welding, we usually program the microcontroller in the PCBA board to enable the microcontroller to achieve specific functions. It will improve efficiency and reduce production costs.

PCBA Test

Including ICT test, FCT test, Burn-In Test, fatigue test

ICT Test (In-Circuit Test): Through the test probe contacting the test point of the PCBA, the main PCBA test circuit continuity, voltage and current value, fluctuation curve, amplitude, noise, etc.

PCB Functional Test Requirements

Before discussing design, test systems, software, and test methods, it is important to understand the “object” – the PCB product to be tested, not only the PCB or final assembly itself, but also how much will be produced, the expected failures, etc., including

Product type

Structure (single PCB / pre-made PCB / final product)

Test specification plan:

test point expected production (per line / per day / per shift, etc.)

Expected failure type

Obviously, the above ignores the “budget”, but only after understanding the above items to determine how much a product test to spend, to figure out what is needed to PCB functional test-the UUT before you start discussing funding issues, and only at this time to know how to make compromises to get the job done.

PCB Functional Test Requirements

PCB Functional Test & Programming Quality Control

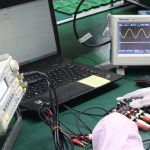

FCT Test (Functional Test):

Firstly we need to program the prepared single-chip microcomputer (MCU) into the program IC through the burner, this step is conducting a simulation test for all PCBA tests. Then it has any questions from hardware and software, we will also be equipped with the necessary patch processing production tooling and test racks.

Burn-In Test:

After the online PCB programming and FCT for the PCB board, we can simulate user input and output for a long time and periodically test its durability and welding reliability.

Fatigue test:

It is mainly to sample the PCBA board, and perform the high-frequency and long-term operation of the function, observe whether there is a failure, and judge the probability of failure in the PCB board testing, so as to feedback the working performance of the PCBA board in the electronic product.

In order to make sure nothing goes wrong, we will carry out strict inspection procedures to ensure the delivery of high-quality products.

Significance of PCB Functional Test

PCB functional test is becoming increasingly important, however, the same as PCB programming online test, the technology development, and PCB design can make the testing scope limited. Although great progress has been made in the PCB testing software environment to help overcome some of the difficulties, if you want to follow your test strategy to successfully implement PCB functional testing, there are many problems to avoid and to do more thorough preparation. PCB functional testing is increasingly being used in post-production line processes and even for mid-process testing, but the systems and implementation methods are almost completely different from those of the past. Today’s PCB functional testing systems are in most cases faster and more compact, and PCB functional testing is indispensable for verifying overall product functionality, maintaining calibration information, providing data to ISO 9000 programs, and assuring the quality of high-risk products. Such as the quality of medical equipment are indispensable.