Medical Device

Almost every medical equipment requires a fully assembled medical circuit board. Ultrasonic therapy equipment and blood pressure monitors are a few examples of standard medical equipment, and all of them count on PCBs to kick in. HX technology aims to provide multiple high-quality medical device products, including ultrasound machine PCB, endoscope PCB and glucometer PCB board.

The trend of PCB Medical Industry

The medical field is not like it used to be. Advances in technology have revolutionized the industry. This change is even more evident in electronic diagnostic, research, and treatment systems and tools. Every day, several complex electronic devices and instruments are introduced to simplify various medical procedures. This growth has largely benefited the PCB industry because, without PCB, new inventions would not be impossible. To meet the ever-changing needs of medical device and diagnostic machine manufacturers, today’s PCB manufacturers are manufacturing extremely simple parts into highly complex printed circuit boards in PCB medical industry. Using specialized high-speed laminates, copper and aluminum substrates, ceramics, and coatings, PCB manufacturers can make these boards best suited for medical industry applications.

Applications of PCB for Medical Industry

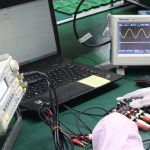

With the development of medical technology, more and more medical diagnostic, research and treatment have advanced, which need computer-aided. It means that medical devices and equipment must have a high level and high precise standard of medical PCB. Therefore, medical PCBA has become more important in medical fields, which is the PCB meaning in medical.

The rapid progress of medical science today is closely related to the development of the electronics industry. A lot of microbiological equipment and other instruments are individually based PCB, such as pH meter, heartbeat sensor, temperature measurement, ECG machine, EEG machine, MRI machine, X-ray, CT scan, blood pressure machine, blood glucose level measurement equipment, incubator, and some other medical equipment.

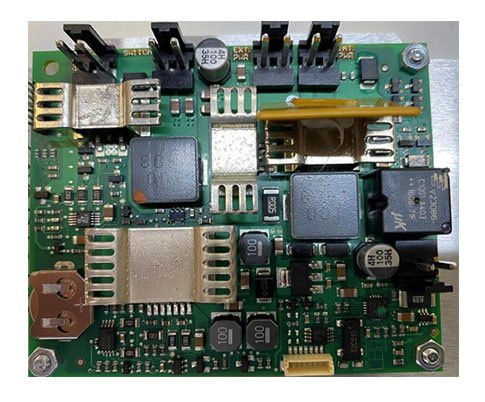

Custom Medical PCB Assembly

Customization of medical PCB assembly is the trend today. The medical industry has chosen the same approach when it comes to PCB. Customers can provide the correct specifications with the full form of PCB in medical for board size in X-direction, board size in Y-direction, total number of holes, minimum alignment and pitch size in inches, board material, number of layers, surface coating, etc. Therefore, the manufacturer will work according to the given specifications and deliver the right product for your application.

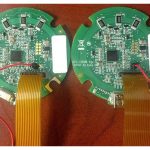

Ultrasound PCB Application of Handheld Medical Equipment

With successive product improvements over the years, and continued innovations throughout the market, handheld ultrasound devices are beginning to unlock their value. Among the early users of handheld ultrasound are cardiologists, who use the device as an initial screening tool in the clinic, at the bedside during rounds, and in interventional units. Other users were more likely to be emergency physicians, especially emergency medical personnel, critical care staff in the intensive care unit, and military personnel. Subsequently, handheld ultrasound has gained some acceptance in procedural ultrasound (including vascular access and anesthesia). Specialists within the department are using handheld ultrasound for rapid examination and initial screening as an adjunct to more powerful on-board systems in hospital departments. Circuit board manufacturers are finding that an expanding customer base, coupled with affordable pricing, has led to global sales of handheld ultrasound PCB.

What is PCB Medical Meaning?

Printed circuit boards (PCB) have an important place in healthcare and medicine. As the industry continues to innovate to provide the best technology for patients and their caregivers. More and more research, treatment and diagnostic strategies are moving toward automation. As a result, more work involving PCB assembly is needed to improve medical devices in the industry. As the population ages, PCB assembly will continue to grow in importance in the medical industry. Currently, PCBs play an important role in medical imaging devices such as MRIs and cardiac monitoring devices such as pacemakers. Even temperature monitoring devices and responsive neurostimulators can be implemented with state-of-the-art PCB technology and components.