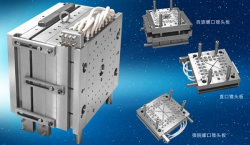

PLASTIC BLOW MOULD

As a blow mold factory, Jeward could offer blowing mould solutions for blow molding machine from 2L to 5000L. We are specialized in the middle-large blowing mould. Our blow mold toolings are applied in food packaging, chemistry, refrigerated transportation, aquatic breeding and aqua-PV, etc.

Advantages of Jeward Blow Moulds

Compared to injection molding, blowing molding technology is more suitable for hollow and large parts like bottle, bucket, box and container. With the development of blowing molding machine and material, blow mold tooling is widely used in the industry area. Now, based on the blowing molding process, multi-layer blow molding and stretch blow molding are developed by Jeward.

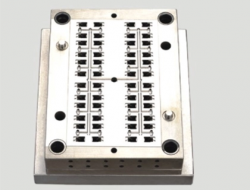

To Mould Lighter And Cheaper Products: Jeward Blow Moulds

Compared to the injection mould, the blow mould made by hollow blow molding machine is lighter and cheaper. Due to its high productivity, blow mold tooling already becomes the primary choice for producing middle or large size hollow products. The chemical barrel, IBC bucket and reservoir produced by blow mold tooling have even wall thickness and good sealing and anti-corrasion function. The blowing buoy and fishing boat have characters like light, good impact resistance, high safety. So it’s widely used in aquaculture industry.