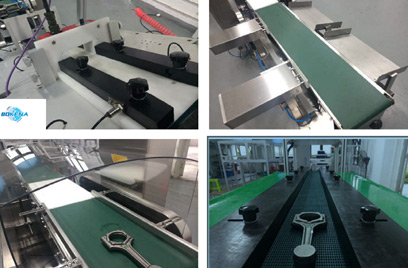

Principle and Characteristic of Eddy Current Testing Instrument

The basic working principle of eddy current testing instrument is as follows:

When the test coil with alternating current is close to the conductor workpiece, the alternating magnetic field generated by the coil will cause the conductor to generate current (eddy current). The size, phase and flow pattern of eddy current are affected by workpiece properties (conductivity, permeability, shape, size) and defects. The voltage and impedance of coil are changed by the reaction of magnetic field.

Therefore, the change of voltage or impedance of the test coil can be measured by the instrument, and the nature, state and defect of the workpiece can be judged.

Characteristics of Eddy Current Testing Instrument

1. Scope of application of eddy current testing instruments

(a) Process inspection and final product inspection: quality control during manufacturing process or rejection of non-conforming products in finished products.

b) In-service inspection: periodic inspection for mechanical parts and heat exchange pipes and other facilities.

c) Other applications: thickness measurement of metal sheets and coatings, material sorting, conductivity measurement, etc.

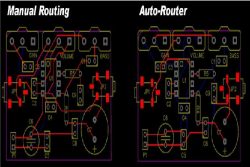

2. Advantages of Eddy Current Testing Instruments

(a) No contact with the workpiece and no coupling agent are needed in the detection, which can be carried out at high temperature. At the same time, the probe can be extended to remote detection, which can effectively detect the narrow area and deep hole wall of the workpiece.

b) The detection sensitivity of surface and near surface defects is very high.

c) It is easy to realize high-speed and high-efficiency automatic detection for the detection of tubes, rods and wires. It can digitally process the test results, and then store, reproduce and process the data.