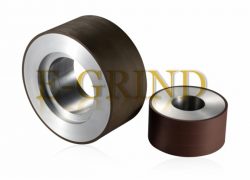

Resin Bond Grinding Wheels

Resin Bond grinding wheels are generally divided into resin bond diamond grinding wheels and resin bond CBN grinding wheels according to abrasives. Henan E-Grind Abrasives Co., Ltd’s Resin Bond grinding wheels have long service life, excellent self-sharpening ability and good shape retention, high grinding efficiency.

Resin Bond Grinding Wheels For Sale

Cut Off Wheels

High-speed steel, mold steel, hardened steel, tool steel, stainless steel, and other ferrous metals can all be cut with the E-Grind CBN cut off wheel.

Grinding Wheels For Woodworking Tools

Diamond and CBN grinding wheels for woodworking tools with good self-sharpness, high grinding efficiency, and long use life.

Tool & Cutter Grinding Wheels

We have a full series of grinding wheels for the whole manufacturing process of tools and cutters, from cutting rods to final CNC grinding.

Grinding Wheels For Die & Tooling

For Die & Tooling grinding, we developed different bonds for grinding steels, carbides, and mixture of steel and carbide, no clogging or glazing.

Centerless Grinding Wheels

Resin bond centerless grinding wheels are widely used for high productivity and mass production of rods, bars and tubes with high precision.

Resin Bond Double Disc Grinding Wheels

E-Grind Resin bond Double disc wheels are widely used for surface roughing and finishing top and bottom of precision parts, such as compressor cylinder, rotors, automobile parts, spring, semi-conductor parts, etc.

Tissue Paper Knife Grinding Wheel

Tissue Paper Knives need to be resharpened online without coolant, E-Grind developed a special CBN grinding wheel and diamond grinding in the resharpening process, with no sparking.

Economical Grinding Wheels

To meet the demand for low-cost grinding wheels, E-Grind develops economical grinding wheels and helped customers save costs.

How Long Does A Diamond Grinding Wheel Last?

Parameters that affect the life of the grinding wheel:

Since the specifications of the grinding wheel and the grinding conditions are intricately intertwined to create the optimum sharpness and life, you will find the best conditions for actual machining by looking at each combination of work, machining conditions, and grinding wheel specifications.

Factors that affect the life of the diamond grinding wheel:

Specifications of the grinding wheel such as abrasive grains, particle size, coupling, concentration, and bond type, together with grinding conditions such as Cutting depth, feed rate, rotational speed (peripheral speed), and type and amount of grinding fluid are all factors affecting the life of the diamond grinding wheel.

FAQs of Resin Bond Grinding Wheels

What is resin bond grinding wheel?

The resin bond grinding wheel is the type of grinding wheel that uses resin as a bond, one of the three elements that make up a grinding wheel. In the case of resin bond grinding wheels, it only represents the bond, so it is necessary to see the specifications in detail to see what purpose and function the grinding wheel has. It is also called a resinoid grinding wheel.

Why CBN wheel, not diamond wheel, for grinding ferrous materials?

Fe, Cr, Ti, Ni, etc, can’t be machined by diamond, because these metal elements will cause a series of chemical reactions, such as oxidation or graphitization reaction with diamond, the diamond grains will wear off quickly during the grinding process of the above-mentioned materials. CBN(Cubic Boron Nitride), as the second hardest material after diamond and with similar properties to diamond, is used for machining non-diamond-machinable metals.

CBN is the best suitable abrasive for grinding ferrous materials. You will hardly generate a high temperature because CBN has an extremely good conductivity for temperature, so the heat generated is dispersed quickly.

How to choose the suitable resin bond grinding wheel?

Proper grinding wheel selection is critical to get a high grinding efficiency and good workpiece quality. According to the material of the workpiece to be ground, we can roughly choose the resin bond grinding wheels with the below principles.

Diamond grinding wheel: Tungsten Carbide, Cermet, Hard metal/steel combinations, Glass, Quartz, Ceramics, Ferrotitanite Graphite, Magnetic materials

CBN grinding wheel: Stainless steel(SS), HarHardened high-speed steel (HSS), High alloyed steels with at least 55 HRC, Case-hardened steels, Iron-based powder coatings, Soft steels, Chill castings, Stellite.