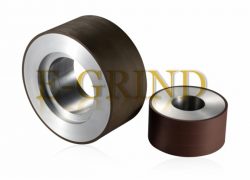

Vitrified Bond Grinding Wheels

The diamond and CBN are held in place by ceramic components that are fused to form the abrasive part of vitrified bond grinding wheels. Bond grinding wheels made of vitrified material offer high grinding efficiency and excellent wheel shape retention.

Vitrified Bond Grinding Wheels For Sale

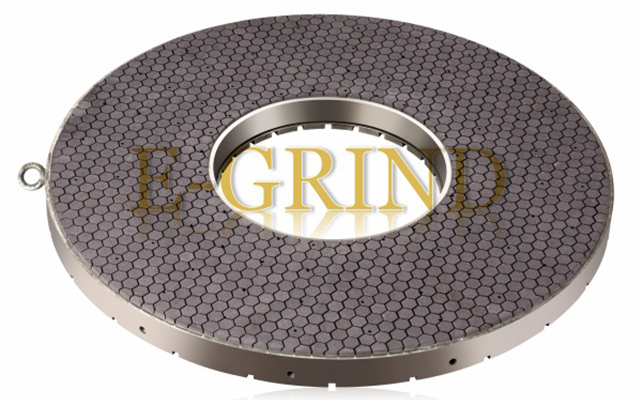

Double Disc Grinding Wheels

Double Disc Grinding can reduce the non-cutting time dramtically, and can achieve automatization and high efficient grinding after installed with automatic loading and unloading mechanism.

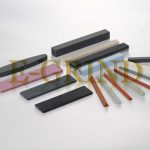

Crankshaft, Camshaft & Cylindrical Grinding Wheels

With long dressing interval and good wheel sharpness, vitrified bond CBN cylindrical grinding wheels are the best choice for grinding crankshaft and camshaft.

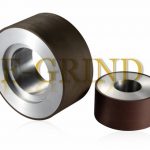

Internal Grinding Wheel

Internal Grinding Wheels are used for grinding all kinds of boreholes on parts, like bearings, cylinders, auto parts, etc.

Vitrified Bond PCD and PCBN Grinding Wheel

For grinding PCD and PCBN tools, vitrified bond diamond wheels can provide high grinding efficiency and tool precision.

Natural Diamond Bruting Grinding Wheels

E-Grind provides high quality diamond grinding wheels for polishing and bruting natural diamonds with longer using life.

How are vitrified grinding wheels made?

Vitrified bond grinding wheels are made from abrasives(conventional abrasives, diamond powder, CBN powder), pore-forming agents, ceramic powder, and body(aluminum, steel, ceramic, etc).

Abrasives, pore-forming agents, and ceramic powder will be pressed and sintered into an abrasive ring first, then stuck on a body.

FAQs of Vitrified Bond Grinding Wheels

What is vitrified bond in grinding?

The vitrified bond is the type of bonding agent in grinding wheel, generally, ceramic powder or glass powder. Vitrified bond has better chemical stability, higher bonding strength, and excellent sharpness.