CNC Machined and Injection Molded Medical Parts Manufacturer

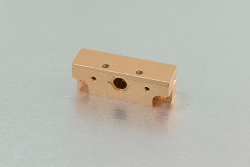

Flourish Legend provides a wide range of equipment components for the medical industry, including plastic parts, metal parts, and medical device enclosures. Our plastic machined parts are manufactured using high-quality plastic materials, ensuring excellent durability and precise dimensions, and guaranteeing reliability and stability within medical equipment. The metal parts include various metal accessories such as screws, nuts, washers, etc., used to support and connect various components of medical devices. Additionally, we offer medical device enclosures designed to provide protection and aesthetic appeal. We are committed to providing the medical industry with components that meet quality standards and safety requirements, ensuring the integrity and superior performance of medical equipment, and providing a safe and reliable medical environment for healthcare professionals and patients.

How to Make Prototype Models for Medical Device Components?

How to Make Prototype Models for Medical Device Components?

In today’s manufacturing technology, plastic prototype models of medical device components are typically produced using methods such as 3D printing, CNC machining, low pressure injection moulding (RIM), etc. Each manufacturing process has differences in product quality and appearance. The choice of production method depends on the specific requirements of the customer, and of course, the cost varies accordingly. Customers can provide 3D drawings, samples, production lists, visual renderings, and silk-screen prints to the manufacturer based on their subjective needs. The manufacturer can generally deliver the physical prototype model to the customer within a few days, while more complex models may have a production cycle of approximately two weeks.