CNC Machining ABS

ABS is a popular thermoplastic material with high impact resistance and toughness which is used in a wide range of applications.

ABS CNC machining is a cost-effective process that allows production of complex geometries and customization of the final product to meet specific requirements. It’s widely used in various industries, including automotive, aerospace, medical device manufacturing, consumer goods, prototyping, and many others.

Application Industries of CNC Machining ABS

Here are some of the notable industries that use CNC Machining ABS:

1. Automotive industry: such as dashboards, safety equipment, engine covers, and trim components.

2. Electronics industry: such as casing, front panels, and mounting brackets.

3. Medical industry: ABS’s biocompatibility makes it an ideal material for producing medical devices and surgical instruments.

4. Consumer goods industry: such as toys, furniture, appliance components, and other household goods.

5. Aerospace industry: such as lighting fixtures, interior panels, and mounting brackets for avionics equipment.

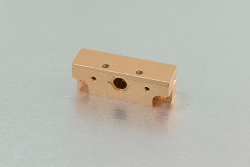

Xintao ABS CNC machining can provide high-quality parts with tight tolerances and dimensional accuracy parts.

Advantages of ABS CNC Machining

Good machinability

Excellent strength

High accuracy and precision

Temperature and chemical resistance

Low cost

Dielectric properties

Lightweight

These characteristics make CNC machining of ABS plastic an attractive and efficient manufacturing process, Xintao, an ABS parts manufacturer with over 10 years of experience, can provide you with professional ABS machining services.