CNC Machining Material

Xintao can process a variety of materials, such as AL, Cu, steel, POM, ABS, etc. Generally, we will do different surface treatment for AL materials to prevent rust, such as oxidation, painting, nickel plating, etc. The choice of material for CNC machining depends on the specific requirements of the project, including the desired strength, weight, cost, and appearance. The versatility of CNC machining allows it to work with a wide range of materials, making it a highly flexible manufacturing process.

CNC Material List

Aluminum CNC Machining

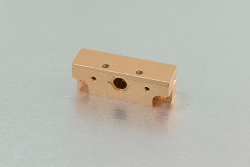

Brass CNC Machining

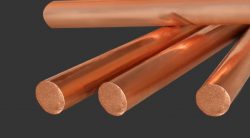

Copper CNC Machining

CNC Machining Stainless Steel

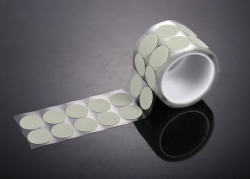

CNC Machining POM

CNC Machining ABS

CNC Machining PEEK

PA (Nylon) CNC Machining

What Should Be Considered When Selecting A Material For CNC Machining?

Part application. The general application scenario will determine the physical properties of the part material, such as tensile strength, strength-to-weight ratio, crack resistance, rigidity or flexibility, etc.

Appearance and the cost of the material. For example, the appearance of consumer products generally require aesthetic and low cost parts.

Operating environment. Operating conditions include temperature, harsh chemicals, exposure to ultraviolet radiation, constant contact with water, and even exposure to flame.”

CNC Machining Applications

CNC machining has a wide range of applications across various industries due to its precision, efficiency, and versatility.