CNC Machining PEEK

CNC Machining PEEK

PEEK (polyetheretherketone) is a high-performance plastic material with excellent mechanical, thermal, and chemical properties.

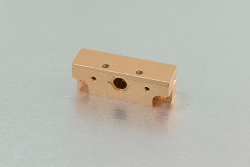

PEEK CNC machining is a cost-effective and efficient manufacturing process that produces parts and products with excellent mechanical, thermal, and chemical properties. The process offers a high degree of design flexibility, dimensional accuracy, and precision, making it suitable for various applications.

Common Applications of PEEK CNC Machining

Here are some common applications of PEEK CNC machining:

1. Aerospace industry: aircraft engines parts.

2. Medical industry: the parts of implants, surgical instruments, and other medical devices

3. Automotive industry: parts that require exceptional strength, such as engine components and structural parts.

4. Electronics industry: electrical insulators, connectors, and other electronic components that require a high degree of strength and resistance to high temperatures.

5. Manufacturing industry: such as bearings, gears, and custom parts in high-temperature environments.

In summary, PEEK CNC machining offers excellent mechanical, thermal, and chemical properties, making it highly suitable for many applications.