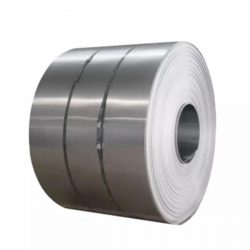

Cold Rolled Coil

Description of Cold Rolled Coil

Cold rolled coil, as known as CR coil, CRS or CRC. Cold rolled steel coils are a farther product that uses hot rolled steel coils to do further processing. The further processed steel coil put in a cold rolling mill where the material is cooled (at room temperature) and then annealed and/or tempered. This process will make the steel coils become smaller dimensional tolerance and a wider surface finish result. In the Chinese market, the product name prefers to name as cold rolling, but the correct product name should be flat sheet or coils. As one of the professional cold rolled steel coil suppliers, HUARO offers high-quality cold rolled steel coil for sale, come and buy cold rolled steel coil at HUARO.

The cold rolled steel coil is made of hot rolled steel coil.

The surface scale can be removed during pickled treatment and the finish mill. The Cold Rolled Steel Coil is farther and thinner than the hot rolled coil. The main difference between the hot and cold rolled steel coil is the thickness, surface treatment, and the rolling temperature.

Main Advantages of Cold Rolled Steel Coil

Cold rolled steel/coils offer a variety of cold rolled steel sheet and coil products and value-added services to meet customer needs. HUARO’s Cold Rolled Steel Coil service capabilities include slitting, shearing, blanking, leveling, degreasing and brushing, and metallurgical support.

Production Process of Cold Rolled Steel Coil

Cold rolled steel coil is rolled at room temperature, below its recrystallization temperature, which enables better control over finished product shape, thickness, dimensions and surface finish. The cold rolling process helps to obtain the CR coils from the cooling (in the cold rolling mill) of hot rolled pickled products (made from finest steel), which is reduced too much finer thickness with increased strength via strain hardening (up to almost 20%). The resulting CR coils are smaller as compared to the coils formed by the hot rolling process, and they are less ductile. They possess improved surface finish and tighter tolerances.

Application of Cold Rolled Steel Coil

Cold rolled steel coils application field usually in which high standard of dimensional tolerances, strength and surface finish quality. The normal industry field for cold rolled steel coils will as below

Metal Furniture

Automobile Components

Electronics Hardware

Home Appliances and Components

Lighting Fixtures

Construction

Dimension

Description

Thickness (mm)

Width (mm)

Length (mm)

Cold-rolled coils

0.35-3

600 -1650

–

Narrow strips

0.35-2

60-599

–

Hot-rolled sheets

0.35-3

600 -1510

750-4000

Minimum and Maximum Weight of Coils

Width (mm)

As rolled (mt)

One cut (mt)

Two cuts (mt)

600 – 690

5.4-10.8

3.5-5.4

2.3-3.06

691-790

6.5-12.3

4.0-6.2

2.7-7.4

791-890

7.5-13.9

4.6-7.0

3.0-4.6

891-990

8.2-15.4

5.1-7.7

3.4-5.1

991-1090

9.3-16.8

5.6-8.4

3.7-5.6

1091-1190

10.2-18.4

6.2-9.2

4.1-6.1

1191-1290

11.0-19.9

6.7-10.0

4.4-6.6

1291-1390

12.0-21.4

7.2-10.7

4.8-7.1

1391-1490

13.0-23.0

7.8-11.5

5.2-7.7

1491-1650

13.5-23.8

8.3-11.9

5.5-7.9